White Paper: Extending Tool Life In Metalworking Operations

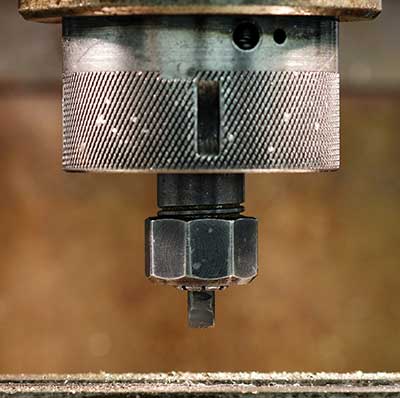

Automated fluid recycling systems maximize the service life of tools while lowering operating costs.By Mike Hook, Sales & Marketing Director, PRAB Introduction The metalworking industry, like all manufacturing operations, must contest with several market factors that are difficult if not impossible to control: Escalating materials costs spurred by policy decisions, transportation costs, raw materials […]