Magnetic chip conveyors transfer wet or dry ferrous scrap without carryover.

PRAB’s magnetic chip conveyors effectively transfer wet or dry ferrous chips, stamping slugs, turnings, parts or die scrap without carryover.

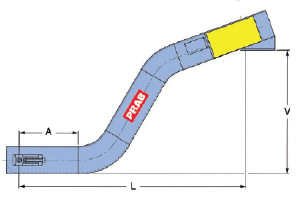

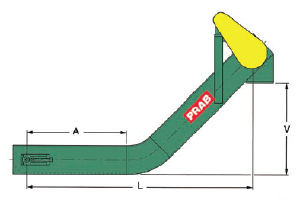

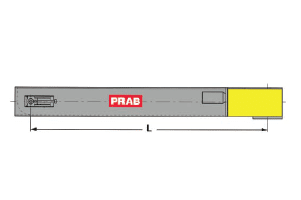

This scrap conveyor system moves material with the aid of permanent ceramic magnets located under a stainless-steel slider bed. An oil reservoir in the base of the conveyor self-lubricates the chain for quiet performance and low maintenance of this scrap handling system.

The PRAB Magnetic Conveyor is available with stainless steel slider bed in smooth or Rigidized® surfaces. This system can be built in a heavy-duty model or as a standard scrap handling system as described below.

PRAB Ferrous Material – Magnetic Conveyor

PRAB’s Magnetic Conveyor transports ferrous material downstream.

PRAB Cast Iron Fittings Magnetic Conveyor

PRAB’s magnetic conveyor transports chromate coated cast iron conduit fittings.

Product Brochures

Product Brochures: Magnetic Conveyors

Other Downloadable Content

Conveyor Solutions

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Download Conveyors Still Operating in the Field After 57 YearsQuiet Performance with No Carryover PRAB’s Magnetic Chip Conveyors effectively transfer wet or dry ferrous chips, stamping slugs, turnings, or parts without carryover. Systems move material with the aid of permanent ceramic magnets located under a stainless-steel slider bed. An oil reservoir in the base of the conveyor self-lubricates […]

This white paper will address how: The most common metal scrap handling challenges facing metal casting operations How the correct conveyor will reduce downtime, lower expenses, improve safety, and provide a long service life Assess Conveyor Design, Construction, and Capabilities to Improve Efficiency, Decrease Maintenance, and Lower Labor Costs By Bob Anspaugh, Conveyor Sales […]

As an Engineering Manager for PRAB, Jason Luzader has experience regarding heavy-duty conveyors. In this latest blog post, he answers a few questions that organizations should consider when searching for a new conveyor system. Q) What are some common factors organizations don’t consider when installing a conveyor? A) A key factor I see customers overlook when installing a […]