Quiet, efficient transfer of all types of machining scrap with the in-floor scrap conveyor.

Convey all types of metal chips, fines and turnings, wet or dry bushy wads, and tramp metal solids, in a liquid-tight trough. Ideal for high-volume coolant-flow applications.

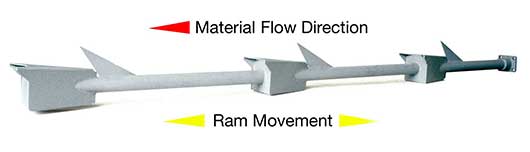

In-floor trough conveyors are available as a free-floating ram design or guided ram scrap removal system.

Harpoon® Conveyor

Push-Bar™ Conveyor

PRAB Harpoon Conveyor

Harpoon Conveyor running moving metal turning through coolant.

Product Brochures

Product Brochures: In-Floor Trough Conveyors

White Paper

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

Other Downloadable Content

Conveyor Solutions

Die Cast Scrap Conveyor Systems

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Proven to Raise Productivity Up To 60% Documented Results Achieved by PRAB Customers Long Lasting Equipment: Conveyors Still Operating in the Field After 57 Years Scrap aluminum from die cast trim presses drop onto oscillating conveyors that feed onto dual under-floor centralized collection oscillators. Oscillating conveyor deposits scrap into a large 6” […]

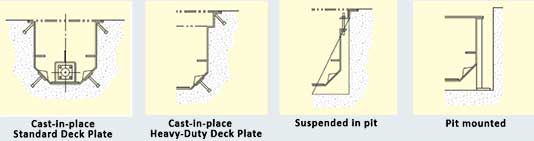

Download Conveyors Still Operating in the Field After 57 YearsLiquid Tight Construction Ideal for High Volume, Coolant Flow ApplicationsPRAB In-floor Trough Conveyors transfer all types of metal chips, fines and turnings, wet or dry bushy wads and tramp metal solids with time and energy saving efficiency. The liquid-tight trough construction is ideal for high-volume coolant flow applications. […]

“We get $0.17 per pound more for our briquetted material over loose chips.”– Jack Rovan, Martin-Baker Plant Manufacturing ManagerProven Results Achieved for PRAB Customers: Documented reduction of scrap volume by as much as 90% Increased scrap value up to 25% Reclaimed up to 99% of cutting fluids “We have seen around […]