Reduce coolant waste up to 90%.

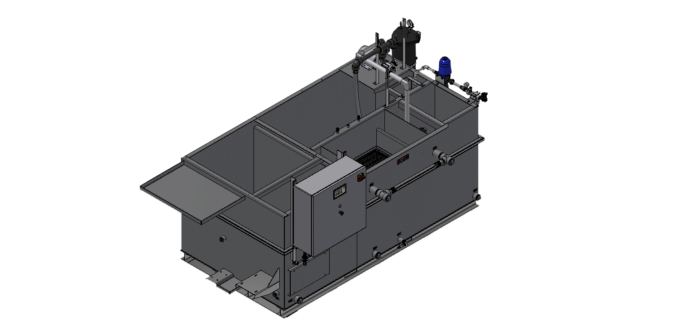

The effective solution to coolant recycling. The PRAB Guardian™ is a centralized system for recycling used coolants, reducing waste fluids up to 90%, and eliminating concerns about wastewater haul-away liabilities. Typical payback in six to nine months.

These versatile and centralized coolant recycling systems remove tramp oils and suspended solids from contaminated coolant, control bacteria and can adjust fluid concentration for fluid recovery. Each turnkey system is designed for easy installation, quick start-up, and simple, efficient operation- clearly making it the best coolant recycling solution on the market today. For a calculation of just how quickly you will pay this system back, call us for a free ROI estimate.

Advantages of PRAB Guardian™ Coolant Recycling Systems include:

Why does the PRAB Guardian Coolant Recycling System succeed when other systems fail? Successful recycling requires particulate filtration, tramp oil removal, coolant concentration control, and bacteria elimination. The integrated Tramp Oil Separator removes up to 99% of free floating and lossy emulsifying tramp oil. This process extends coolant life, resulting in up to 75% savings on coolant purchases.

The unit removes mechanically dispersed tramp oil through a coalescing media compartment that is self-cleaning. The porous media pack is highly efficient, offering an optimum ratio of coalescent area in open space to pull the maximum amount of tramp oil from the fluid. PRAB’s weir design guarantees the highest purity of oil for maximum value. The PRAB Guardian is available in three different configurations.

Base

The PRAB Guardian’s base configuration includes the following components:

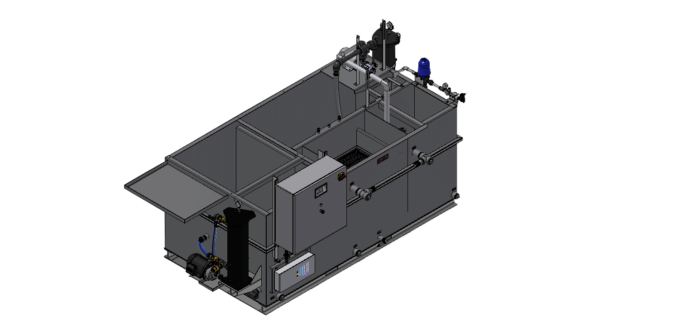

Standard

The PRAB Guardian’s standard configuration features all of the components included in the base version as well as some additional elements. Specifically, this package includes a polishing filter assembly that is typically 20-micron rated and a Coolant Manager. Proven to kill up to 99.9% of coolant bacteria, the Coolant Manager is a safe, economical solution that generates and injects Ozone directly into the coolant.

This specific treatment extends coolant life up to 25% and eliminates odors, clogged coolant lines, and slime in sumps. As a result, this decreases the likelihood of employee health issues. Additionally, the coolant manager reduces biocide use and oxidizes bacteria, viruses, cysts, spores, hydrogen sulfate (egg odor), and other contaminants both organic and inorganic.

Base configuration:

Additional features included in the Standard configuration:

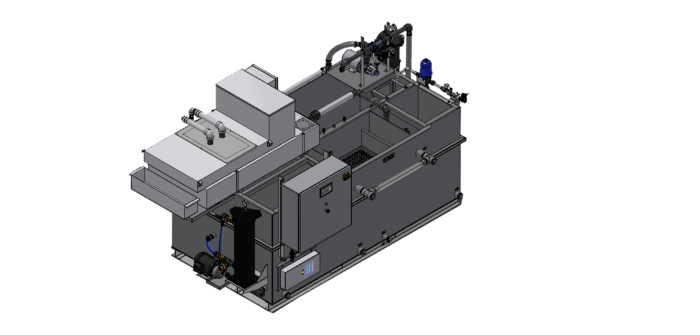

Deluxe

As the most robust Guardian package, the deluxe configuration includes every feature found in the standard version as well as some other components. In lieu of an inlet basket strainer, the deluxe uses a Paper Bed Filter with 10-micron rated media. A dirty coolant transfer system is also implemented.

Base configuration:

Additional features included in the Deluxe configuration:

AC³

A fully automated coolant concentration controller that is compatible with HG1200 units and above, the AC³ will maintain set concentration levels within +/- 0.5% accuracy. The exclusive logic built into the controller allows more or less concentrate to enter the discharge flow of the Guardian system. This comprehensive system provides the necessary intelligence to accurately and automatically inject new concentrate only as needed to maintain optimum ratios and achieve maximum tool life.

| Model | Processing Rate | Dirty/Clean Tank Capacity | Length | Width | Height |

|---|---|---|---|---|---|

| HG400 | 10 gpm | 200/200 gal | 89″ | 73″ | 72.5″ |

| HG600 | 10 gpm | 300/300 gal | 126″ | 74.5″ | 76.6″ |

| HG800 | 15 gpm | 400/400 gal | 154″ | 76.5″ | 78.8″ |

| HG1200 | 15 gpm | 600/600 gal | 168.6″ | 77.5″ | 86.1″ |

| HG1600 | 25 gpm | 800/800 gal | 179.8″ | 90.3″ | 94″ |

| HG2000 | 25 gpm | 1,000/1,000 gal | 174″ | 91.3″ | 101″ |

| HG4000 | 25 gpm | 2,000/2,000 gal | 250″ | 91″ | 148″ |

Product Brochures

Product Brochure: Guardian Coolant Recycling Systems

Product Brochure: Coolant Manager

Product Brochure: Coolant Concentration Control

Product Brochure: Mobile Sump Cleaner

Product Brochure: Sump Cleaner Transport Options

Case Studies

Case Study: Aerospace Components Manufacturer Reduces its Environmental Impact and Cuts New Coolant Purchases by 75%

Case Study: Aerospace Components Manufacturer Turns Its Waste Stream into a Revenue Stream

Case Study: Auto Parts Manufacturer Reduces Coolant Purchase Costs and Eliminates Used Coolant Disposal in First 12 Months

Case Study: Cameron International Improves Profitability, Reduces New Coolant Purchases by Recycling Coolant with Guardian System

Case Study: Cashing in Your Chips

Case Study: Iowa Industrial Hydraulics Reduces Coolant Waste by 90% with Installation of a PRAB Guardian 400

White Paper

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

White Paper: Getting the Most Value from Metal Scrap and Spent Fluids

White Paper: Green Engineering

White Paper: Making Wastewater Compliance Part Of A Profit Strategy

White Paper: Reducing Haul-Away Costs in Metalworking Operations

White Paper: Prioritizing Plant Housekeeping In A Metalworking Operation

Other Downloadable Content

PRAB Fluid Filtration Solutions Product Selection Chart Brochure

PRAB Fluid Filtration Systems and Wastewater Treatment Brochure

PRAB Filtration Spectrum Brochure

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

PRAB completes comprehensive sample testing to establish an accurate understanding of the unique characteristics of your mixed solution and its industrial applications. This test determines the correct centrifuge system design and capacity to optimizes the filtration process within your facility

When you’re ready to get started, contact us or request a material test.

Introduction to the Guardian and How it Works

Successful coolant filtration requires three components (1) particulate removal, (2) tramp-oil removal, and (3) coolant concentration control. The Guardian™ Coolant Recycling System incorporates all three elements—not just pieces—for maximum coolant life. This combination makes it the most efficient option for centralized recycling of metalworking cutting fluids. If your current process is labor intensive, requires a lot of downtime for sump maintenance, or lacks the capacity to handle all the fluid, it’s time for a change. In this video, see how the PRAB Guardian recycles your spent cutting fluids to significantly decrease coolant spend and eliminate tramp-oil issues.

Proven to Reduce Your Coolant Waste Up to 90% The Effective Solution to Coolant Management Problems PRAB’s Guardian Coolant Recycling System is a centralized, economical solution to the high costs associated with maintaining water-based coolants and washwater in the metalworking industry. The Guardian system recycles used coolants, reducing waste fluids by up to 90%, and eliminates concerns […]

Download Automatic Coolant Concentration Control Automatically control the concentration of coolant in your Guardian™ Coolant Recycling System The AC3 Fluid Monitor is an economical in-line process refractometer. The unit’s simple design has only one piece: a detection unit with an affixed digital display. Instead of interrupting an automated process, the embedded processor tests for Brix continuously while the […]

Metalworking operations are often faced with unavoidable costs that are beyond their control. Two of the largest this year have been tariffs, and the cost of cutting fluids. Fortunately, there are many back-end solutions to help offset these costs that will add more value to metal scrap and spend fluids, and move profit margins in a positive direction. Machine […]