5 steps for improving waste stream processing – Aerospace Manufacturing Design

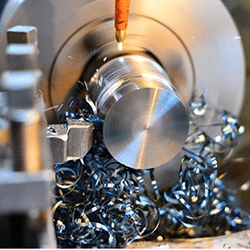

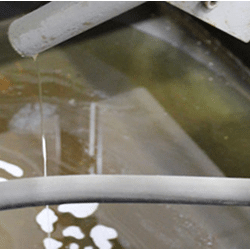

For an industry characterized by technological advancements, many aerospace manufacturers are slow to elevate waste management and recovery processes. Too often, these processes are considered secondary to production. That approach will gradually cut into an organization’s bottom line, as environmental compliance becomes more tightly regulated and the shift to the circular economy accelerates. Aerospace manufacturing facilities have the potential to […]