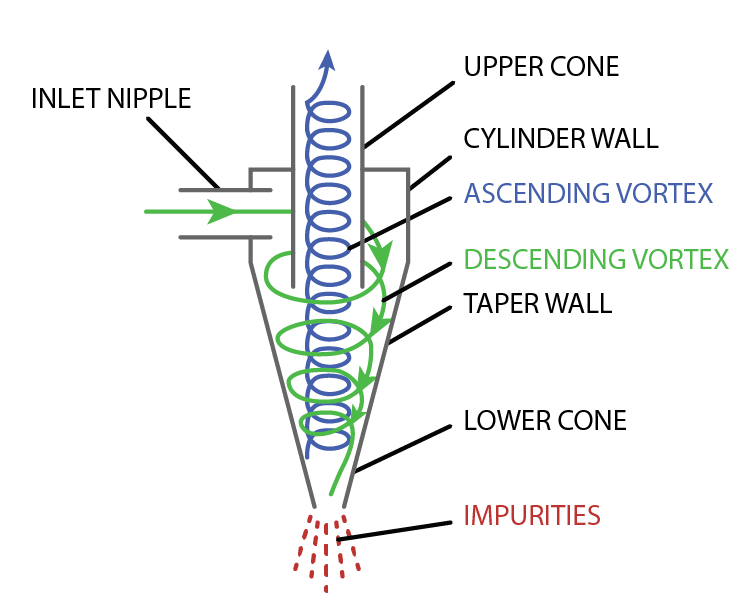

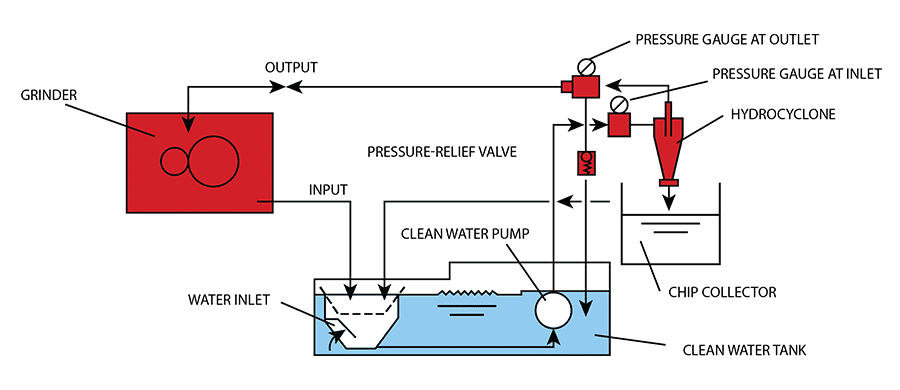

Replacing filter media is time-consuming and expensive. The Hydrocyclone creates ascending and descending vortexes in a cylindrical feed that separates contaminants from coolant without the use of filter media. This design results in consistent, long-term filtration.

| Model | Number of Hydrocyclones | Contaminated Water Flow Rate (GPM) | Clean Water Supply Flow Rate (GPM) | Pressure at Outlet (PSI) | Max. Pressure (PSI) | Feed Pump (HP) | Feed Pump Motor |

|---|---|---|---|---|---|---|---|

| HC-F1 | 1 | 10.5 (40 L/min) |

8 (30 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

1 hp (0.75kw) |

50/60HZ 200/220V |

| HC-B1 | 1 | 18 (70 L/min) |

14.5 (55 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

2 hp (1.5 kw) |

50/60HZ 200/220V |

| HC-B2 | 2 | 37 (140 L/min) |

29 (110 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

2 hp (1.5 kw) |

50/60HZ 200/220V |

| HC-B3 | 3 | 55 (210 L/min) |

43.5 (165 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

3 hp (2.2 kw) |

50/60HZ 200/220V |

| HC-B4 | 4 | 74 (280 L/min) |

58 (220 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

3 hp (2.2 kw) |

50/60HZ 200/220V |

Accidents and injuries in the workplace are going down in the US, but the costs associated with them continue to go up. There is a long way to go in reducing these costs, especially in certain areas of the metalworking industry. Fortunately, there are solutions available to decision-makers when they choose to seriously consider the application and benefits provided […]

Download printable PDF Anthony Screw Products Ltd. is a precision machining company located in Burlington, Ontario, Canada. The company utilizes automatic multi-spindle machines, CNC lathes and mills, and rotary transfer machines to produce a wide range of custom parts including mining, tank and hydraulic fittings, washers, nuts, bolts, pulley hubs, and speaker parts. The privately owned, family-run business […]

Lower Metal Scrap and Fluid Haul-Away Expenses with Automated SystemsBy Mike Hook, Sales & Marketing Director, PRAB Introduction Costs to haul away and dispose of metal scrap and spent cutting fluids erode the bottom line of metalworking operations. Several factors outside the control of metalworking shops contribute to the costs, which continue to increase: […]