Revolutionize Your Lithium – Ion Battery Recycling Through New KMC Global Partnership

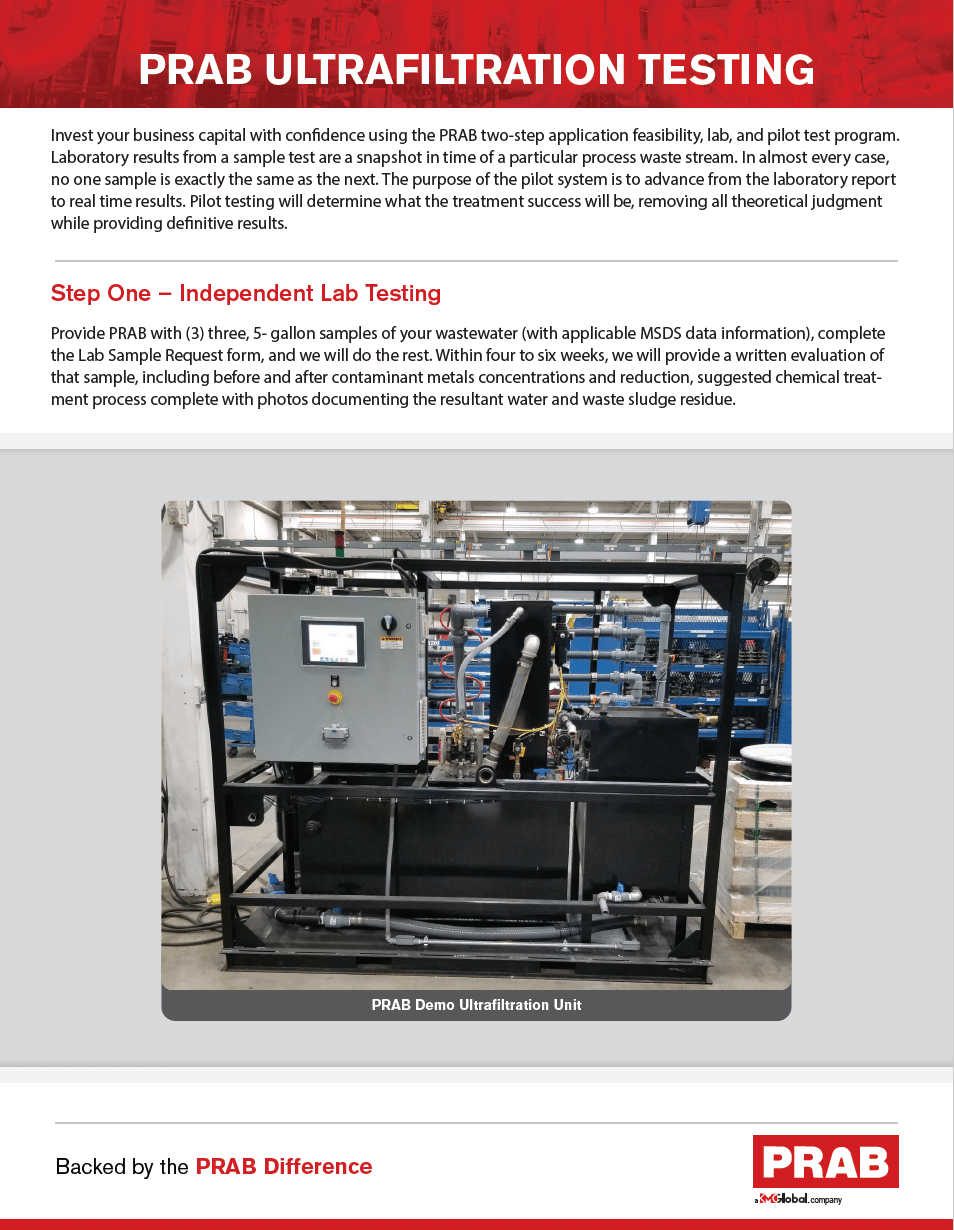

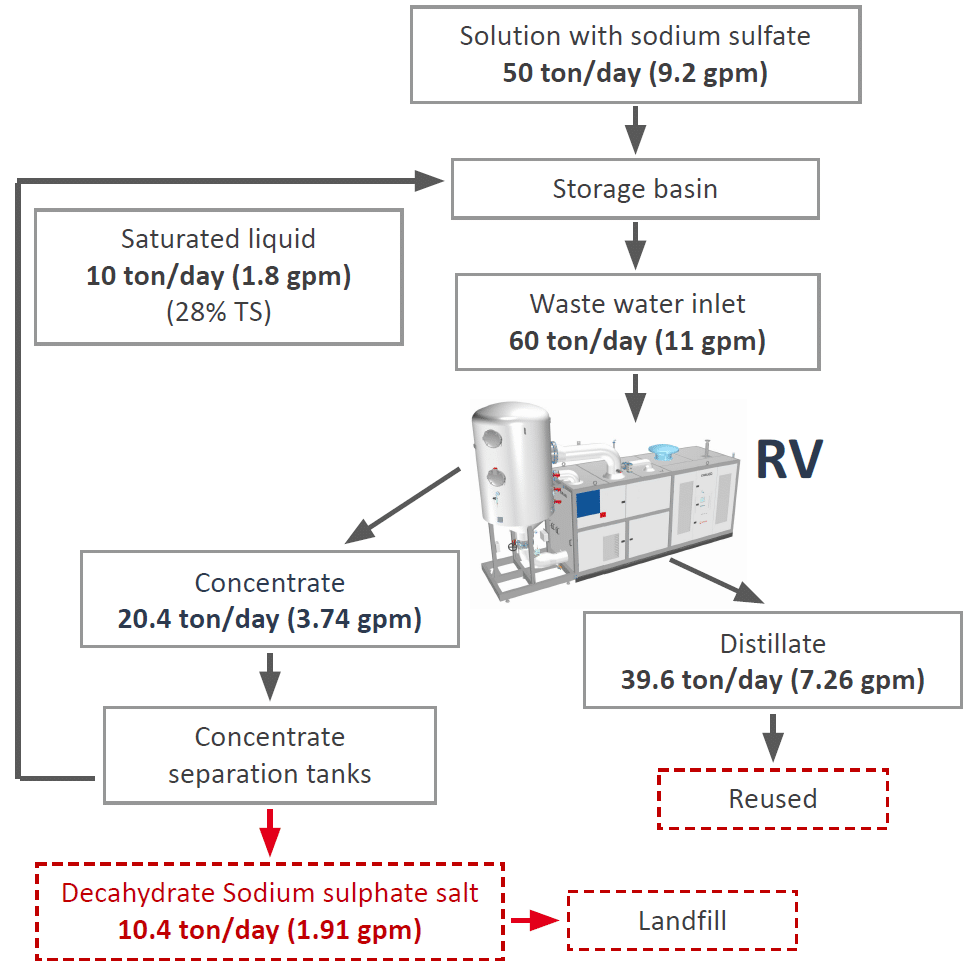

With demand increasing for Lithium-Ion (Li-ion) battery recycling, KMC Global is pleased to announce a partnership with Design Systems Inc. and BC Construction Group that will develop turnkey, state-of-the-art Li-ion battery recycling operations. The alliance between the two companies and KMC Global (dba PRAB, Hapman, Triple/S Dynamics, CDM Systems, and OVibra) will employ a design-build delivery approach, ensuring a […]