Reduce volumes of large bundles and stringy turnings. This scrap metal equipment delivers dry, shovel-grade chips and reclaims up to 99% of valuable coolants and cutting oils.

PRAB High Volume Aluminum Systems

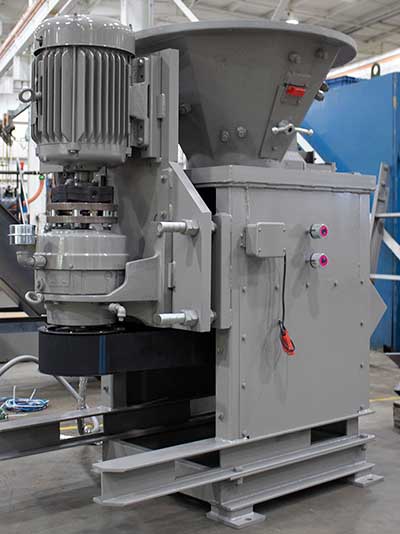

Aluminum turnings are one of the most difficult types of material to process, especially in large volumes. PRAB delivers the reliable, durable, and dependable aluminum processing system your operations demand. The skid steer loader feeds wet, stringy material into the hopper of the 6” pitch steel belt conveyor. The PRAB Steel Belt Conveyor carries the material up and meters it into the crusher. The crusher reduces the stringy chips into smaller, flowable chips and discharges them onto the PRAB Drag Conveyor. The PRAB Drag Conveyor transports the material up and into two diagonal shaft chip wringers. The PRAB Chip Wringers separate the coolant from the chips using nearly 700 Gs of centrifugal force. The settling tank captures the coolant for recycling. An integral PRAB Drag Conveyor discharges the settled fines back into the material flow. The PRAB Chip Wringers internally generate air pressure to pneumatically discharge dry chips. The dry chips travel through the pneumatic piping and cyclones to the PRAB Magnetic Separator. The PRAB Magnetic Separator removes ferrous particles from the stream of material and discharges them into a container, while dry aluminum chips continue onto the weight belt. The weigh belt measures throughput of dry material in process and deposits it into a blower. The blower pneumatically transports the chips across the plant to one or more cyclones, which dissipate the air and deposit the chips into storage bunkers.

Product Brochures

PRAB Chip Processing Systems All Product Brochure

White Paper

White Paper: Green Engineering

Other Downloadable Content

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Product Brochure: PRAB Diagonal-Shaft Wringer

Download Leverage Favorable Lending Conditions and Automated Equipment’s ROI to Limit Impact on Cash FlowBy Mike Hook, Sales & Marketing Director, PRAB IntroductionFor many manufacturers, 2020 was a crash course in operational survival. What do we need to do to keep employees safe from a pandemic? How do we rectify supply chain disruptions? How do we maintain production levels? […]

“We get $0.17 per pound more for our briquetted material over loose chips.”– Jack Rovan, Martin-Baker Plant Manufacturing ManagerProven Results Achieved for PRAB Customers: Documented reduction of scrap volume by as much as 90% Increased scrap value up to 25% Reclaimed up to 99% of cutting fluids “We have seen around […]

Located in Burlington, Ontario, Canada, Anthony Screw Products Ltd. is a precision machining company that produces a range of custom parts including fittings, washers, nuts, bolts and pulley hubs. Company President Rod Anthony has more than 25 years of experience working in every position in the plant’s manufacturing process. Even with this unique and total understanding of the operation, he […]