The PRAB ScrapVeyor™ features leak-proof construction that retains 100% of cutting fluids when moving scrap to its destination, and positive discharge provides a clean operation while eliminating carryover. Combine this scrap conveyor with a distribution system to maximize operational load-out efficiency.

This fully automated and liquid-tight scrap conveyor with positive discharge provides a clean operation when it comes to die scrap, chip processing and material handling. Combine this scrap conveyor with a distribution system to maximize operational load-out efficiency.

Features

Options

Load out options include: manual, powered or fully automated swivel chutes or a manual or automatic tipping chute. Load out systems can be used with single, dual and full size trailer or railcar applications.

Image Right: Auto lube systems are designed to automatically supply a small quantity of clean grease or oil to bearings on a regular basis-improving bearing performance and eliminating maintenance required for manual greasing.

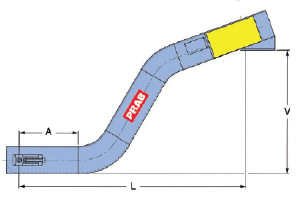

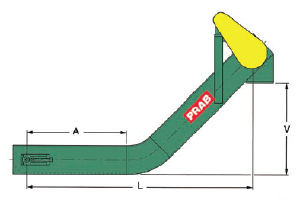

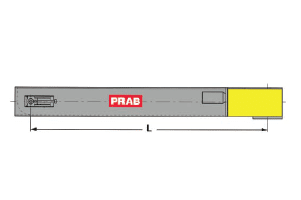

Trough designs are available in flat or V-style (symmetrical and off-set) formations to meet the needs of your stamping scrap handling systems application, with the following configuration options.

PRAB Stamping Scrap ScrapVeyor

PRAB’s ScrapVeyor moves stamping scrap in its fully sealed trough which reduces housekeeping maintenance.

Product Brochures

Product Brochure: ScrapVeyor II Conveyors

Case Studies

Case Study: Cashing in Your Chips

Case Study: Metalworking Company Finds Increased Asset Utilization by Focusing on Scrap Management

White Paper

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

Other Downloadable Content

Conveyor Solutions

Die Cast Scrap Conveyor Systems

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Conveyor Performance White Paper

Automating the handling of metal scrap and spent fluids is crucial to protecting your workforce.By Mike Hook, Sales & Marketing Director, PRAB Introduction In a report issued during the 2018 National Safety Council Congress & Expo, the Campbell Institute-a respected global thought leader on placing environment, health, and safety at the core of […]

KMC Global (dba Hapman, PRAB, Triple/S Dynamics, CDM Systems, and OVibra) is using decades of expertise to provide solutions for battery recycling operations. The battery recycling process requires a variety of equipment to properly separate, capture, and refine metal ions. Experience in conveyors, process equipment, and process water solutions makes KMC Global the smart choice for these operations. […]

There isn’t an employer in existence that shouldn’t consider slips and falls to be a significant safety concern in its facilities. In an article about overlooked hazards and risk zones in the workplace, Facility Executive magazine cites some sobering numbers: Same-level slip and fall accidents are the leading cause of workplace injuries and totaled almost 200,000 in 2015, according to […]