Blog: Productivity and Cost Improvement Through Metal Scrap & Fluid Management

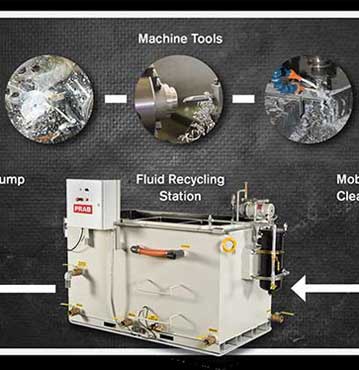

Productivity improvements in today’s manufacturing plants and machine shops are typically derived from the evaluation of the machining equipment, operating procedures, and labor allocations associated with process-side activity. Often the metalworking waste streams; consisting of metal and cutting fluids are overlooked as a place for productivity improvements due to an assumption that a collect-and-dump approach is the most cost-effective […]