Metal Scrap Conveying EquipmentProven to Raise Operator Productivity up to 50%

PRAB still operates conveyors sold over 62 years ago in the field, a strong testimony to our brand’s robust design. Thirteen customizable conveyor options are available for moving wet or dry metal scrap from machining, stamping, die casting, or laser-cutting operations. PRAB conveyors have been proven to raise productivity by 50% and increase worker safety by up to 25%.

Metal Chip Processing EquipmentDocumented Increase in Scrap Value up to 25%

PRAB’s Metal Chip Processing Equipment is engineered to dramatically reduce the volume of machining scrap by up to 91%, transforming bulky metal turnings into small, flowable chips that are easier to handle and transport. Through precision shredding or crushing, these systems prepare metal scrap for optimal recycling and reclamation. Integrating additional processing such as wringing or briquetting further enhances the value of your recovered materials by efficiently separating cutting fluids from metal chips—helping you recover up to 98% of spent fluids and increase scrap value by as much as 25%.

Every PRAB system is built for long-term performance and proven ROI. To help you verify results for your specific materials, PRAB invites you to test before you buy through a complimentary materials testing program. This free service allows you to see the performance of PRAB’s chip processing technology firsthand and receive detailed data on fluid recovery and scrap value potential. Learn more or request your free test at PRAB MATERIALS TESTING.

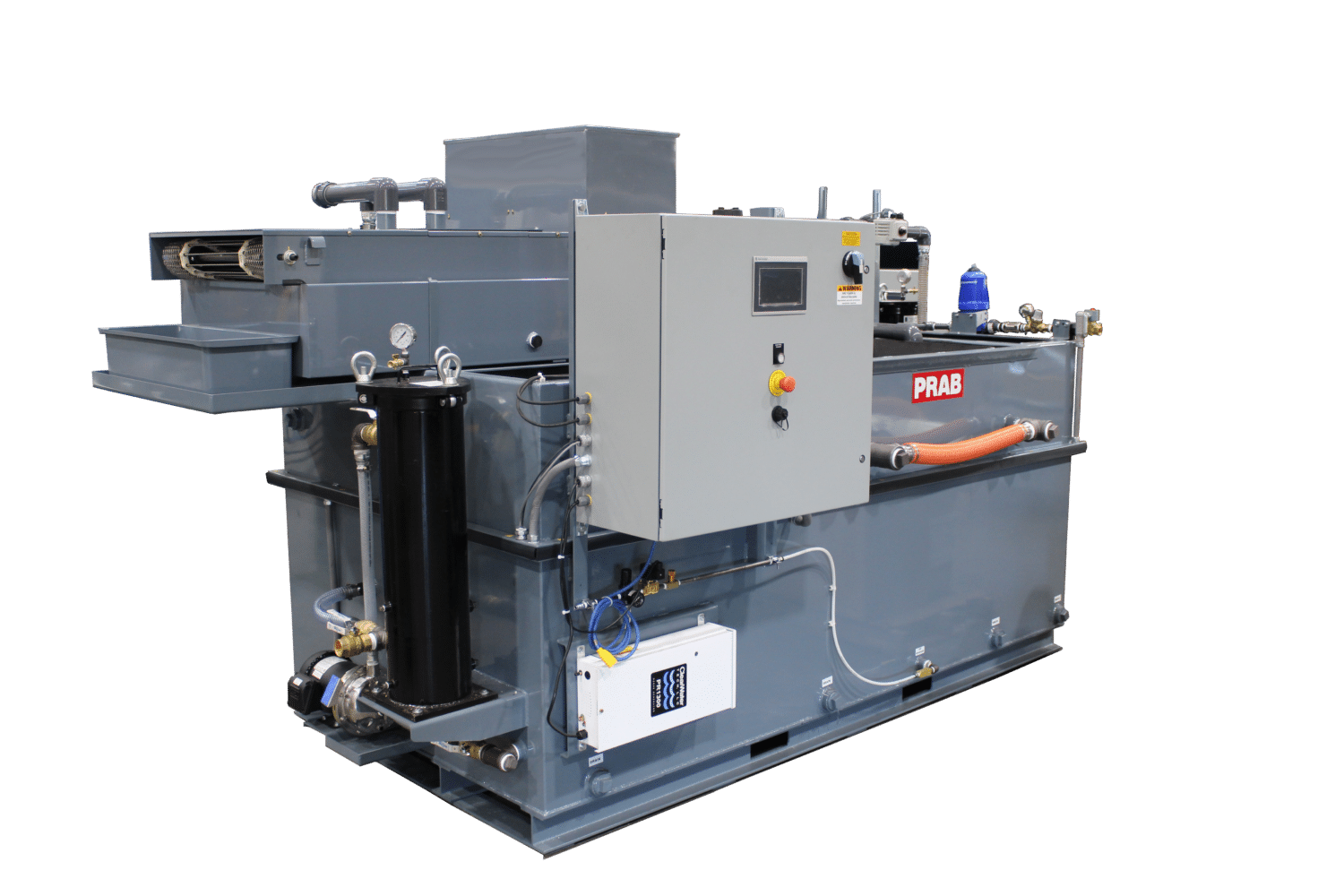

Fluid Filtration EquipmentProven to Reduce New Fluid Purchases up to 75%

PRAB customers have reported a reduction in operational costs of up to 90% by utilizing our fluid recycling equipment, with a payback period of just 6 to 9 months. To effectively address various fluid management challenges, they can choose between centralized systems or machine-side systems.

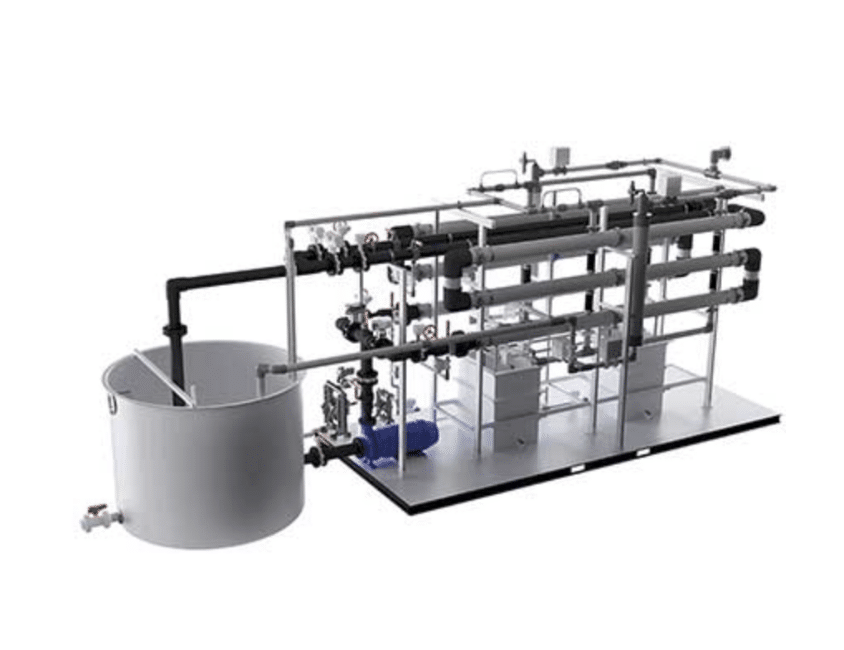

Incoming Water, Process Water, and Industrial Wastewater EquipmentReduce Fluid Waste Disposal as much as 99%

PRAB offers everything you need to effectively treat incoming water, process water, and industrial wastewater. Our technology is designed for easy installation, quick startup, and efficient operation, which helps reduce both maintenance and monitoring. Start treating your incoming water, process water, and industrial wastewater to reduce haul-away costs by up to 90% while ensuring compliance with environmental regulations.

Our Water Pretreatment, Process Water, and Industrial Wastewater Treatment Solutions are successfully used in many industries, including metalworking, oil and gas, mining, chemicals, pharmaceuticals, healthcare, food and beverage, and more.