Elevate oily, thin gauge scrap without carryover.

PRAB’s Pivot Belt Conveyors with Rigidized™ belt surface prevents scrap from sticking to the belt, and its exclusively-designed pivoting hinges flip scrap into hoppers.

PRAB pivot belt conveyors have a Rigidized™ belt surface that prevents scrap from sticking to the belt, and the exclusively-designed pivoting hinges flip scrap into your hopper. This scrap conveyor includes a seamless one-piece pan that collects oily fluids below, reducing housekeeping headaches while keeping workers safer and more productive.

Advantages of the PRAB Pivot Belt Conveyor includes:

Image Right: Auto lube systems are designed to automatically supply a small quantity of clean grease or oil to bearings on a regular basis-improving bearing performance and eliminating maintenance required for manual greasing.

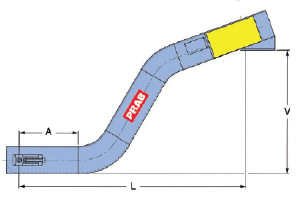

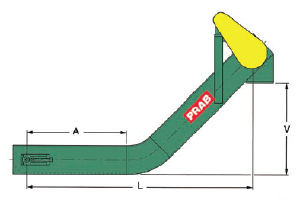

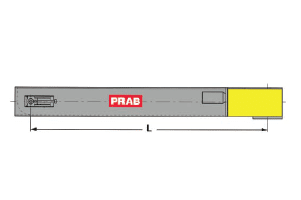

PRAB’s Pivot Belt Conveyors are available in 2 1/2″ to 4″ pitch, designed to convey materials ranging in a various weights and bulk densities. Multiple configurations are available.

Product Brochures

Product Brochure: Pivot Belt™ Conveyors

White Paper

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

Other Downloadable Content

Conveyor Solutions

Stamping Scrap Conveyors & Systems

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Download Proven to Raise Productivity Up to 60%Customers are Experiencing Increased Productivity and SafetyPRAB’s Pivot Belt™ Conveyor with Rigidized™ belt surface prevents scrap from sticking to the belt, while exclusively designed pivoting hinges flip scrap effortlessly into your hopper. Raised pusher flights keep material moving while the seamless, one-piece pan beneath, collects oily fluids to reduce housekeeping […]

Proven to Raise Productivity Up To 60%Documented Results Achieved by PRAB Customers Enhanced Productivity Downtime Before PRAB: 3-4 hours Downtime After PRAB: 2 minutes Safer Workplace “Our process of disposing metal scrap has become more ergonomic and safer.” – Jack Rovan, Martin-Baker Long Lasting Equipment: Conveyors Still Operating in the Field […]

When looking into adding a new, or additional conveyor system to an operation it is imperative to know the major considerations when researching and selecting the right piece of equipment. Every type of metal scrap and shop process is unique, so it is important to prioritize the aspects of a conveyor system most vital to your needs. Conveyor Selection […]