Efficient, High-Volume Fluid Filtration Systems

PRAB’s line of vacuum filters eliminate high sludge volume produced in machining centers and grinding applications. Systems range from standard off-the-shelf units to custom-engineered designs, with filtration capability up to 3,000 GPM for efficient, high volume fluid filtration.

Permanent Media Backflush Process

PRAB Vacuum Filters are virtually maintenance-free, with high sludge volume elimination resulting in lower production costs and continuous operation which decreases downtime. Industrial filtration equipment is available in permanent and disposable media models.

Features & Benefits of PRAB vacuum filtration systems for fluid reclamation include:

Mon-A-Vac™ Disposable Media Vacuum Fluid Filtration Systems

The PRAB Mon-A-Vac™ is a disposable media vacuum filter that maximizes contaminant removal. Filters utilize a vacuum chamber to draw dirty coolant through the disposable filter media. They apply the proven principle of optimal filtration through contaminate or sludge build-up, forming a cake on the filter media. Filtration is maximized as caking builds up on the media. Standard vacuum filter units are available with flow rates up to 3,000 GPM.

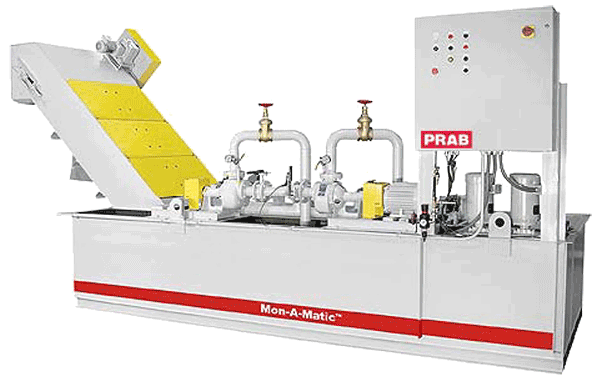

Mon-A-Matic™ Semi-Permanent Media Vacuum Fluid Filtration Systems

The PRAB Mon-A-Matic™ is a semi-permanent media vacuum filter that removes particulate down to 10 microns. This vacuum filter uses a synthetic filter media to reduce operational costs while providing fine particulate removal. Backflushing the filter with clean coolant keeps the filter clean and eliminates the need for large volumes of air. The backflushed solids drop from the filter element and settle into a tank where they are removed via an automatic chain dragout.

PRAB Vacuum Filtration – Permanent Media Backflush Process

Product Brochures

Product Brochure: Mon-A-Vac™ Disposable Media Vacuum Fluid Filtration Systems

Product Brochure: Mon-A-Matic™ Semi-Permanent Media Vacuum Fluid Filtration Systems

White Paper

White Paper: Green Engineering

White Paper: Taking Control of Wastewater Treatment

Other Downloadable Content

PRAB Fluid Filtration Solutions Product Selection Chart Brochure

PRAB Fluid Filtration Systems and Wastewater Treatment Brochure

PRAB Filtration Spectrum Brochure

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

PRAB completes comprehensive sample testing to establish an accurate understanding of the unique characteristics of your mixed solution and its industrial applications. This test determines the correct centrifuge system design and capacity to optimizes the filtration process within your facility.

To receive a free test contact us today at (800) 968-7722.

According to UN.org, more than 80% of all the wastewater from our homes, cities, industry and agriculture flows back into the ecosystem via lakes, rivers and other bodies of surface water, polluting the environment while losing valuable nutrients and other recoverable materials in the process. Guy Ryder, the Director-General of the UN International Labor Organization (ILO) and the Chairperson of […]

Proven to Decrease Fluid Disposal Costs By Up to 90% Documented Results Achieved by PRAB Customers: REDUCED COOLANT COSTS “We have seen around a 75% savings on new coolant purchases.” – Alexandre Blinov, Koss Aerospace INCREASED OIL SAVINGS “Over $212,000 a year in oil savings. I am in shock along with everyone else in my […]

“We get $0.17 per pound more for our briquetted material over loose chips.”– Jack Rovan, Martin-Baker Plant Manufacturing ManagerProven Results Achieved for PRAB Customers: Documented reduction of scrap volume by as much as 90% Increased scrap value up to 25% Reclaimed up to 99% of cutting fluids “We have seen around […]