How Briquetters Maximize Processing Efficiency and Commodity Value – American Recycler

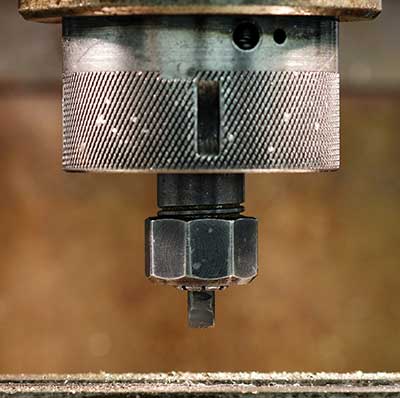

When demand is high for metal, injecting efficiencies into metal scrap recycling processes can create a definitive financial reward for metal scrap recyclers and machine shops alike. One pathway to realizing that reward? Briquetting metal scrap. How Briquetters Work Briquetting machines compress metal chips, loose turnings, and swarf to create compact, dense, uniform pucks that decrease metal scrap volume and […]