Reverse Osmosis filtration effectively removes dissolved salts, colloidal and suspended matter.

Reverse Osmosis filtration removes up to 99.5% of dissolved salts and virtually all colloidal and suspended matter from the most challenging waste and feed water applications. This technology is typically used for industrial, metalworking, and surface treatment applications as a final process after ultrafiltration or chemical treatment of incoming water, process water, or industrial wastewater.

PRAB offers Reverse Osmosis (RO) systems for incoming water, process water and industrial wastewater treatment ranging in capacity from 1 gpm (1440 gpd) to 200 gpm (288,000 gpd). This process which removes up to 99.5% of dissolved salts and virtually all colloidal and suspended matter from the most challenging waste and feed water applications. Our RO filtration technology is typically used as a final process after ultrafiltration or chemical treatment of waste and feed water in industrial, metalworking, and surface treatment applications.

All industrial filtration equipment is built using components only with proven membrane technology that will provide reliable, long-term operation. PRAB RO systems arrive at your site fully tested and ready to clean contaminates from water. PRAB also provides the pretreatment equipment and chemistry required to ensure the optimal performance and lifespan of your RO membranes.

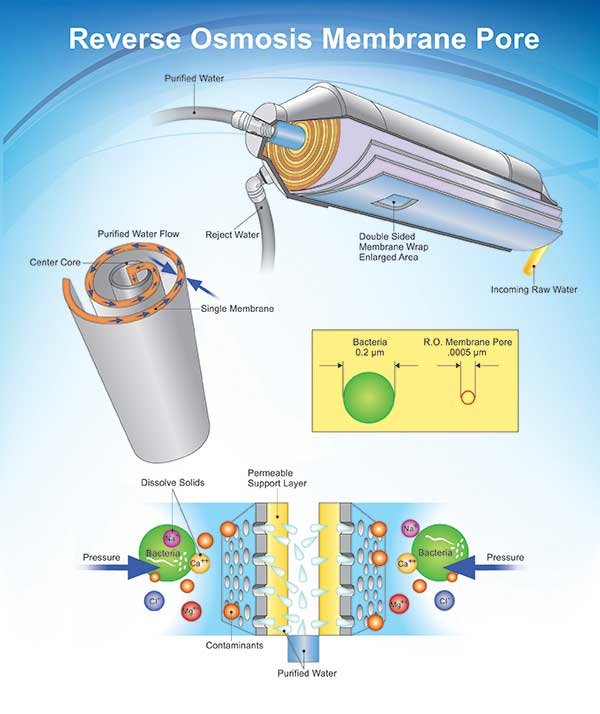

Reverse Osmosis (RO) is a filtration technology used to remove dissolved solids and impurities from water using a semi-permeable RO membrane which allows the passage of water but leaves the majority of dissolved solids and other contaminants behind. RO membranes require high water pressure (greater than osmotic pressure) to work effectively. Water that passes through the RO membrane is called permeate and the dissolved salts rejected by the RO membrane are called concentrate. An RO system that is properly designed and operated can remove up to 99.5% of incoming dissolved salts and impurities.

PRAB offers a complete line of pilot equipment that can be used to validate system operation and performance prior to purchase. Available pilot units include our tramp oil removal, centrifuges, ultrafiltration, vacuum distillation and Reverse Osmosis equipment. Pilot units are meant to act as a sample test to provide confidence that the recommended equipment will meet the output requirements of your application. Flow rates range from 2 gpm (2,880 gpd) up to 10 gpm (14,400 gpd).

Below are a few example system flow diagrams featuring a Reverse Osmosis system. Each solution is customized to your unique application according to your goals and requirements.

Reverse Osmosis (RO) has become a widely utilized treatment process for many applications and particularly treatment of industrial and municipal wastewater. PRAB offers many RO Membrane arrangements for utilizing this advanced technology. Within the industrial sector we focus on improving incoming water, process water, and treatment of wastewater for reuse, and or discharge to your local POTW.

Industrial applications PRAB has participated in include boiler water, chemicals, metal working wastewater, surface treatment, plastics, paper & pulp, pharmaceutical, and food & beverage.

We approach each application as a new study and require completion of a data collection form to capture important information for analysis purposes thereby allowing us to recommend the correct RO arrangement for each project. Information required on the data collection form includes; pH, TDS, COD, BOD, operating temperature, Chloride, Ammonia, Oil & Grease, TSS, Sulfates, Ca, Mg, and Emulsified Oil & Grease. It is also always good to receive a complete laboratory analysis of the wastewater prior to our recommended RO equipment strategy.

Reverse Osmosis has proven capable of removing most dissolved solids in process water or wastewater by pressing the incoming feed water through a semipermeable membrane. The solids can include a range of ions, metals and very limited suspended solids. RO reverses a natural process known as osmosis, which is the act of passing molecules through a membrane from a less concentrated solution into a more concentrated one, equalizing concentrations for the solutions on each side of the membrane.

Pretreatment is important when working with reverse osmosis membranes due to the nature of their spiral wound design. These membranes are engineered in such a fashion as to allow only one-way flow through the system. As such, the spiral wound design does not allow for back-pulsing with water or air agitation to scour its surface and remove solids. Since the accumulated material cannot be removed from the membrane surface systems, they are highly susceptible to fouling (loss of production capacity). Therefore, pretreatment is a necessity for any Reverse Osmosis System.

PRAB offers several pre-treatment options including pH adjust, particulate filtration, activated carbon and other multi-media filters. We also find in certain applications Microfiltration, Ultrafiltration, and in some cases, biotreatment are becoming popular and necessary for RO pretreatment.

All these pre-treatment options will assist in making your RO system run more efficiently and prolong membrane life.

As we further investigate each application its important to know that PRAB mitigates risk by performing lab test and analysis with each prospect’s water / wastewater sample. These tests take place at our Kalamazoo office followed by independent analysis at Certified laboratories.

Once we are sure of the RO system design we create an in-depth proposal for review that includes a clear scope of supply with analysis data included based on the test samples run. What this means to our customers is a complete understanding of the project scope, costs, and assumptions made during the testing and proposal process.

Full Spectrum Industrial Wastewater Recycling and Reuse. Cost Reduction, Waste Minimization & Environmental Compliance.

Agenda

Product Brochures

Product Brochure: Reverse Osmosis Systems

Wastewater System Examples

Automotive Assembly Plant Wastewater System Example

Metal Finishing or Plating Rinse Water Wastewater System Example

Waste Recycling System Example

Multi-Stream Industrial Wastewater Treatment System Example

Technical Briefs

Technical Brief: Eliminating Soluble Heavy Metal Ions From Industrial Wastewater by Precipitation and Ultrafiltration

White Paper

White Paper: Green Engineering

White Paper: Making Wastewater Compliance Part Of A Profit Strategy

White Paper: Taking Control of Wastewater Treatment

Other Downloadable Content

PRAB Fluid Filtration Solutions Product Selection Chart Brochure

PRAB Fluid Filtration Systems and Wastewater Treatment Brochure

PRAB Filtration Spectrum Brochure

PRAB Industrial Water & Wastewater Treatment Systems Brochure

PRAB Industrial Water & Wastewater Treatment Technologies Brochure

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Most of the hazardous waste in surface finishing comes from wastewater that is generated by rinse water. Due to the substantial amount of this waste, within this $155 billion dollar industry, companies are taking quick action to mitigate the environmental risk associated with dumping, and consumption. One of the major steps is though pollution prevention planning and water conservation. […]

KMC Global (dba Hapman, PRAB, Triple/S Dynamics, CDM Systems, and OVibra) is using decades of expertise to provide solutions for battery recycling operations. The battery recycling process requires a variety of equipment to properly separate, capture, and refine metal ions. Experience in conveyors, process equipment, and process water solutions makes KMC Global the smart choice for these operations. […]

Proven to Reduce Water Costs Up to 99% Removes up to 99.5% of Dissolved Salts and Virtually all Colloidal and Suspended Matter PRAB Reverse Osmosis (RO) Systems effectively remove dissolved salts, colloidal, and suspended matter from the most challenging waste and feed water applications. It is typically used as a final process after ultrafiltration or chemical […]