Customer The Client is a global leader manufacturer in Taiwan specialized in optoelectronics and it produces TFT-LCD panels and all kinds of display applications.

Customer’s Needs The Client has acquired the ISO 50001 energy management certification and the ISO 14045 eco-efficiency assessment. In addition the Client is targeting a 25% reduction of carbon emissions in all its premises by 2015 and needs to achieve a relevant reduction in sludge production and relative disposal costs, complying with the local environmental legislation.

|

Parameters |

u.m. |

Waste in |

Distillate out |

Concentrate out |

|

pH |

– |

6-6.5 |

9 |

– |

|

Conductivity |

μS/cm |

<35,000 |

<900 |

– |

|

TS at 105°C |

% |

0.6-5 |

– |

30 |

|

Chloride |

ppm |

<400 |

<10 |

– |

|

Ammonium |

ppm |

1,000-9,000 |

<50 |

– |

|

Copper |

ppm |

4,500 |

<10 |

– |

|

Sulphates |

ppm |

9,000 |

<10 |

– |

|

Technology Type |

Material |

Footprint (m²) |

|

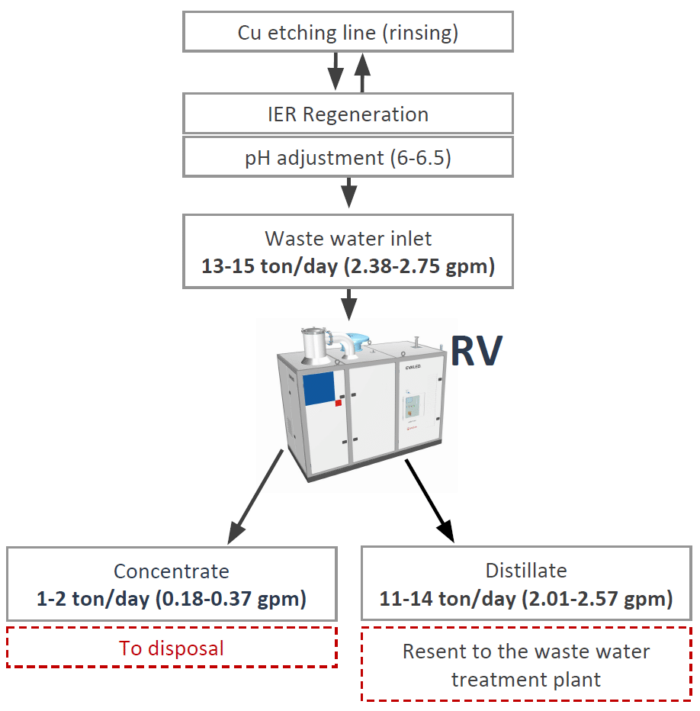

RV F 15 AA |

AISI 316 |

10.5 |

|

Parameters |

u.m. |

Waste in |

Distillate out |

Concentrate out |

|

pH |

– |

6-6.5 |

9 |

– |

|

COD |

ppm |

80,000 |

<4,000 |

– |

|

Conductivity |

μS/cm |

<50,000 |

<500 |

– |

|

TS at 105°C |

% |

9-11 |

– |

30 |

|

Chloride |

ppm |

<500 |

<10 |

– |

|

Ammonium |

ppm |

500-15,000 |

<10 |

– |

|

Copper |

ppm |

6,000 |

<10 |

– |

|

Sulphates |

ppm |

6,000 |

<10 |

– |

|

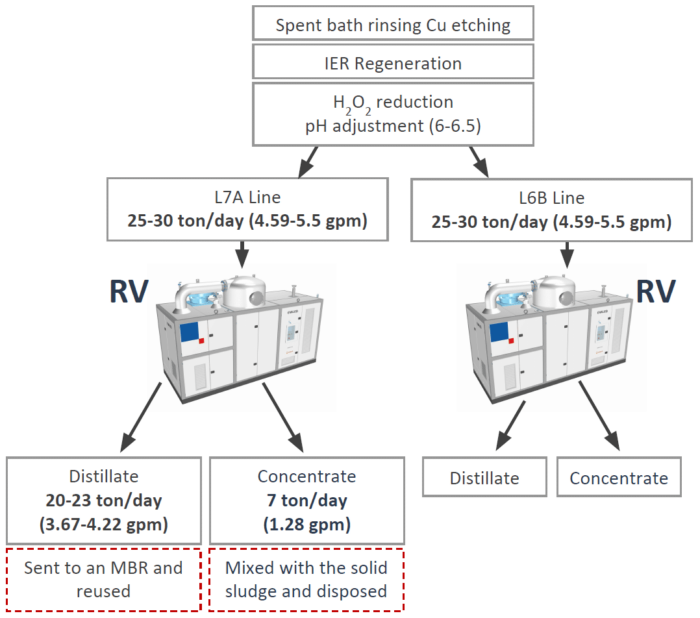

Technology Type |

Material |

Footprint (m²) |

|

2 x RV F 30 AA |

AISI 316 |

2 x 14 |

Water separated: 70-90%

Concentration factor: 4-10 times