Don’t Let Crude Oil Costs Get in the Way of Your Operation’s Goals

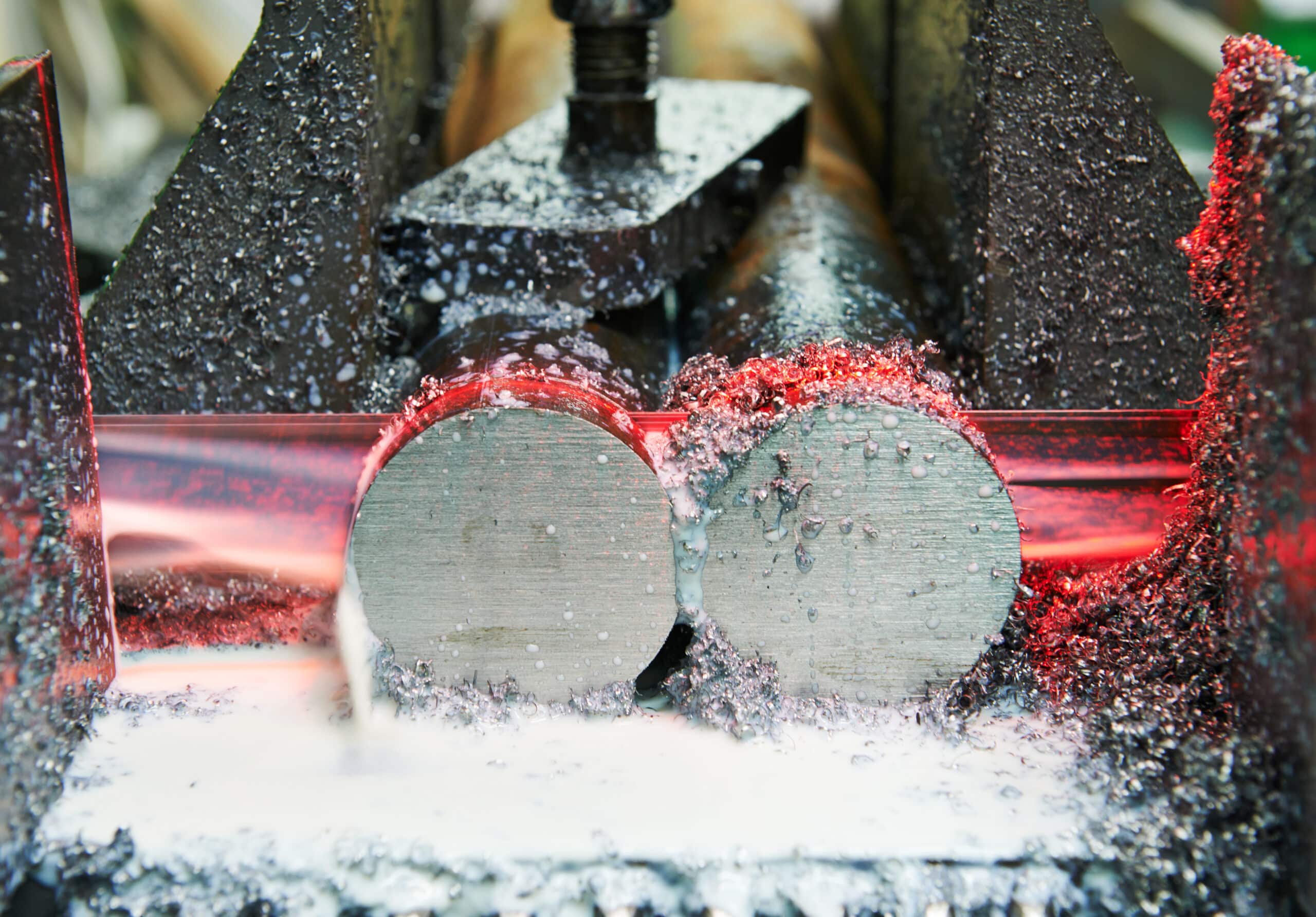

A lot goes into a successful metalworking operation, from a skilled workforce to reliable equipment. Chief among these components is the effective cooling of tools and workpieces. This is where metalworking fluids like coolants and lubricants come into play, as they reduce the heat and friction produced by machining processes. Without these fluids, corrosion within the unit and raw […]