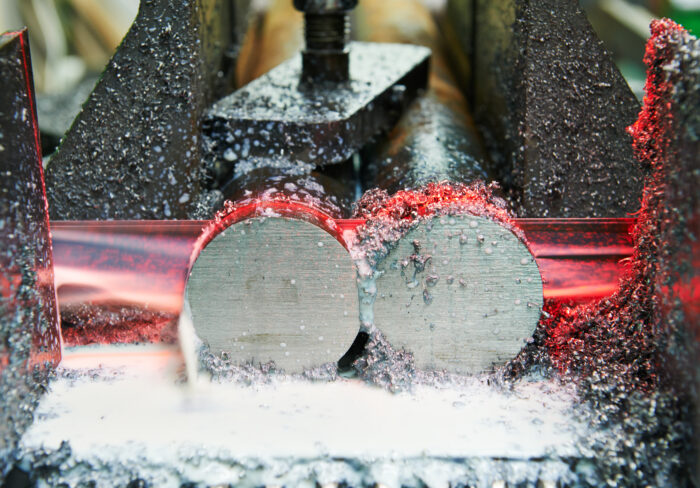

A lot goes into a successful metalworking operation, from a skilled workforce to reliable equipment. Chief among these components is the effective cooling of tools and workpieces.

This is where metalworking fluids like coolants and lubricants come into play, as they reduce the heat and friction produced by machining processes. Without these fluids, corrosion within the unit and raw tears in the material would occur.

Regardless of whether the solution consists of straight oils, or some form of semi-synthetic, crude oil is a key ingredient in metalworking fluids. Due to this significance, an increase in crude oil prices can have severe implications for metalworking operations.

Last month, crude oil prices increased by 2%. It must also be noted that the global output of crude oil is still lower than its pre-pandemic numbers. Considering these trends, and the increasing likelihood of a recession, metalworking operations may face increased pressure to secure coolants and lubricants. Luckily, investing in fluid filtration technology is an excellent way to lessen this economic strain.

Used to separate solids from liquids, vacuum filtration eliminates high volumes of sludge produced by machining and grinding applications. PRAB’s Mon-A-Vac™ Vacuum Fluid Filtration Systems come in a variety of designs with the capacity of up to 3,000 GPM. In terms of models, the Mon-A-Vac has designs that utilize disposable or semi-permanent media.

Ideal for metal processing applications that require the removal of fines without using a disposable media, centrifuges are useful at extracting ferrous and non-ferrous solids from metalworking fluid. PRAB’s Solid Bowl Centrifuges reach flowrates up to 50 GPM and are available in manual, semi-automatic, automatic, and specialty models.

Paper bed filters are also effective at separating ferrous and non-ferrous metals from metalworking fluids. PRAB’s Paper Bed Filters are available in standard, drum-type, and stainless steel models. The flowrate of these models can reach up to 500 GPM. They can also be fitted with Magnetic Separators to remove heavy volumes of ferrous metals prior to the filter media.

Each of these technologies can be effective standalone solutions for dealing with increased coolant costs, depending on the needs of the operation. Alternatively, if a more centralized solution is required, a coolant recycling system could prove to be the smart choice.

PRAB’s Guardian™ Coolant Recycling Systems can reduce up to 90% of an operation’s waste fluids and eliminate wastewater haul-away liabilities while generating payback in six to nine months. They can also reduce new fluid purchases by up to 75%. Don’t let a potential increase in crude oil prices put your organization at a disadvantage. Contact PRAB and put our expertise to work.