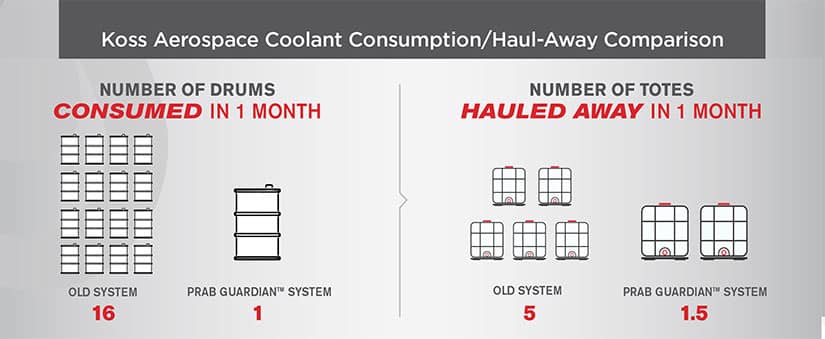

Emptying the sumps of Koss Aerospace’s 26 machining centers was labor intensive and caused a lot of downtime. Their old system’s inability to handle this level of fluid resulted in foul odor and excessive haul-away costs.

PRAB’s Guardian™ Coolant Recycling System with Coolant Manager, Polishing Filter System and Dirty Transfer System

75% savings on new coolant purchases. Operational improvements including increased productivity, efficiency and tool-life.

Established in 1975, Koss Aerospace is a vertically integrated Tier-1 manufacturer of aircraft components and assemblies for commercial aerospace and defense customers worldwide. The company produces various structural parts and landing gear components, ribs and spars, floor and cross beams, winglets, bulkheads, seat tracks and stringers with in-house capabilities for machining, processing and assembly, resulting in a seamless integration of functions. Koss Aerospace also offers integrated manufacturing solutions for highspeed multi-axis machining, complete metal finishing, assemblies, kitting, program management and supply chain management.

As a Gold Certified Supplier to some of the world’s largest aerospace companies, Koss Aerospace takes its environmental responsibility seriously and is always looking for ways to reduce its environmental impact. The company has taken a number of key steps to improve overall efficiency and eliminate waste as part of its commitment to lean manufacturing, continuous improvement and green initiatives.

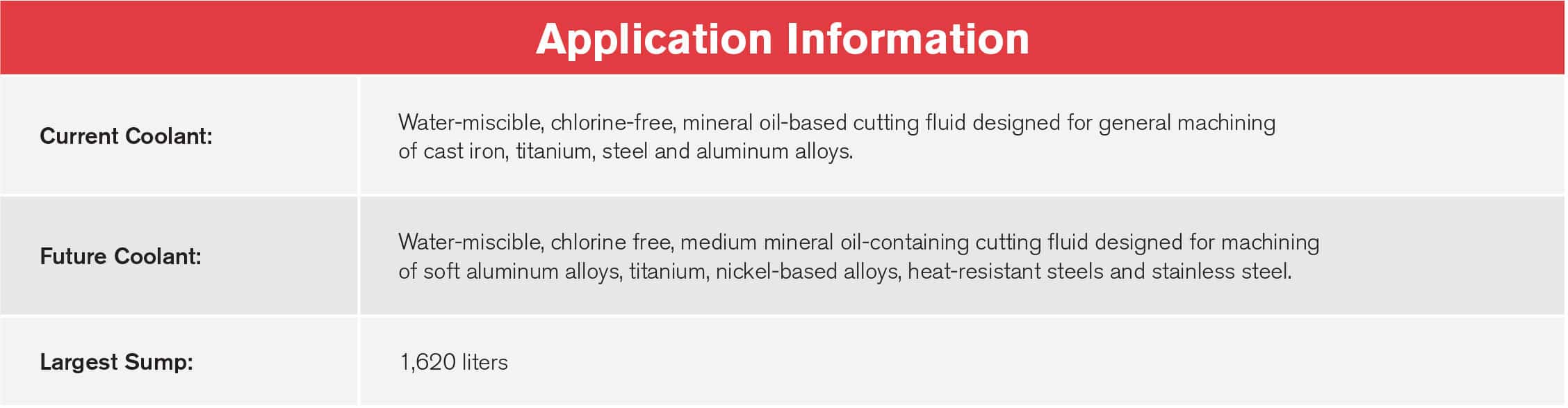

Among the most concerning aspects of the Koss Aerospace operation was the excessive production of waste cutting fluid, which was accompanied by the obvious, foul odor caused by bacteria and fungus in the spent coolant. The company’s previous recycling process involved a simple coalescence system that was labor intensive, required a lot of downtime for sump maintenance, and lacked the capacity to handle all of Koss Aerospace’s 26 machining centers with an average sump size of 500 liters (the largest having a 1,620-liter capacity).

Because of the old system’s inability to handle this level of fluid, the company was disposing of the excess spent coolant (which involved moving the fluid around with a mobile sump cleaner) and incurring significant haul-away costs. In total, Koss Aerospace was discarding coolant at a rate of 4 totes (or 4,000 liters) per week.

Founder and President Drago Cajic, Vice President David Cajic and Maintenance Manager Alexandre Blinov had heard about PRAB several years earlier and remembered the name while researching new recycling solutions. They explored several options and ultimately chose PRAB’s Guardian™ Coolant Recycling System due to its greater capacity, ease of maintenance, and potential for significant coolant savings. The Guardian system also offered additional options including the Coolant Manager, an ozone generator designed to address the issues associated with the growth of bacteria, fungus, and mold.

With the primary criteria being ease of use and the ability to clean the company’s coolant to maximum capacity, Alexandre worked with PRAB Fluid Filtration Specialist Ben McNinch and PRAB Engineer Chris Jones to specify the solution. After Drago and David gave their final approval, Alexandre installed the system while PRAB Service performed the final inspection and personnel training to ensure proper operation prior to start-up. Because the Guardian system was “plug and play”—only requiring connections for water, air and power—it was up and running within two days.

Koss Aerospace began seeing operational improvements almost immediately in a variety of areas as a result of installing the PRAB Guardian system:

In addition, haul-away costs are lower because there is no longer a need to dispose of excess fluid that – in the past – went above capacity. The combined savings from coolant consumption and spent fluid disposal has been significant:

From the engineering department to the finance department, Koss Aerospace employees have noticed a difference throughout the plant since the installation of the Guardian system. Perhaps the most apparent has been an end to the unpleasant smell in the air caused by bad coolant. Equipment operators in particular have seen major improvements in tool life and uptime. Drago, David and Alexandre have been so pleased with the system’s performance that they are discussing adding a PRAB briquetter to further increase their savings. They are also encouraging their coolant supplier to recommend PRAB filtration systems to their other customers.

With the new system, we have seen around a 75% savings on new coolant purchases. I would recommend this equipment to any other company that is producing parts or having similar issues that we were,” Alexandre said. “We received the exact system and results we were promised and are very happy with the system.

Guardian Coolant Recycling System:

Model HG-1200

Coolant Manager: Model CM-778 (Set of 2)

Standard Polishing Filter System

Replacement Filters

Dirty Transfer System