Proven Dependability With Simple Operation

The Sump Cleaner (HSC) has been proven effective in extending the life of valuable metal-working fluids and coolants. The HSC is perfect for the removal and filtration of grinding swarf, dry sludge, metal chips, and other particulates. It is designed for simple, low-maintenance operation to effectively and efficiently remove solid contaminants from machine tool sumps and other tanks and pits. All units are constructed of carbon steel and other high-grade materials, making the HSC ideal for severe industrial applications. The HSC simplifies industrial fluid c larification and handling at a cost that all shop owners will find attractive. The sump cleaner features 100-gallon-per-minute pumping capacity and up to a 600-gallon holding capacity. This system provides an easy, inexpensive way to stay on schedule with your machine fluid maintenance program. The HSC is a single-element vacuum system incorporating a pre-filter specifically designed for solids removal. The HSC is simple to operate, completely mobile and is easily maneuvered in even the tightest shop floor plan. A suction hose removes contaminated product from the machine sump. The fluid is drawn through the internal filter basket and is stored within the cleaner. Each unit is equipped with an overfill protection device to discontinue operation and protect the vacuum.

The Easiest, Most Effective Way to Keep Your Fluid Maintenance Program Working

The HSC simplifies industrial fluid c larification and handling at a cost that all shop owners will find attractive. The sump cleaner features 100-gallon-per-minute pumping capacity and up to a 600-gallon holding capacity. This system provides an easy, inexpensive way to stay on schedule with your machine fluid maintenance program.

The HSC is a single-element vacuum system incorporating a pre-filter specifically designed for solids removal. When metalworking fluids are heavily loaded with swarf and chips, a 2.3- or 5.0-cubic-feet, high-volume filter is available. This filter is capable of holding up to 800 pounds and is safely emptied with a forklift or a hook hoist. The filter media consists of a perforated metal sheath with a polypropylene mesh sleeve and is specially designed to prevent bridging and sticking. Filters are available in assorted mesh sizes to accommodate varying filtration requirements.

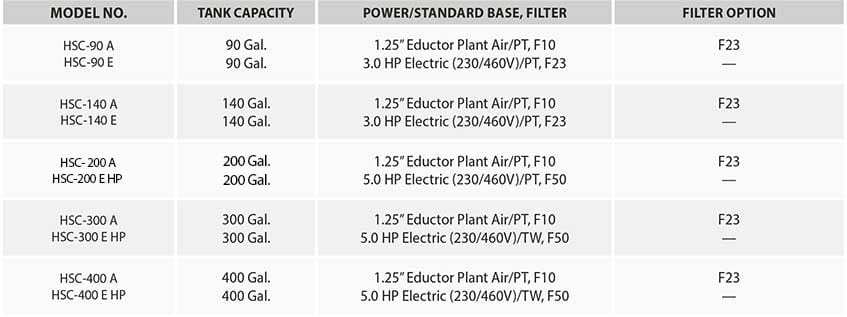

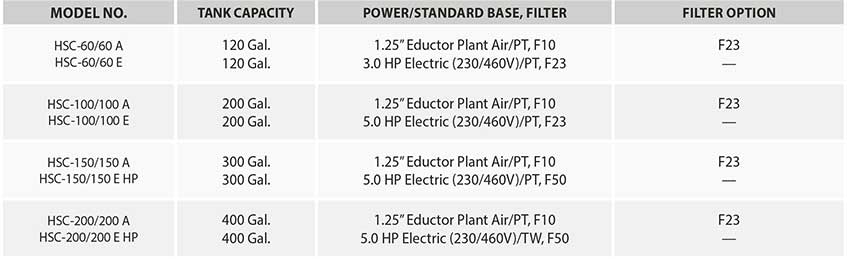

Split Tank Sump Cleaners (Filtered Dirty Coolant / Clean Side):

Notes:

Notes:

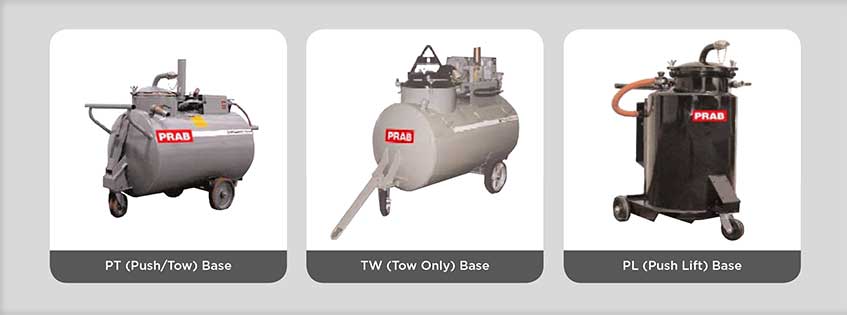

PRAB sump cleaners are available in several transport base options in addition to the standard bases. Tow larger sump cleaners using two- or four-wheel trailers; Walk sump cleaners to move through narrow aisles and tight quarters; Lift smaller sump cleaners with forklifts; and Drive large sump cleaners that travel long distances

PT (Push/Tow) Base

Hand push and short haul tow operation. Can be pushed by one person or towed by tug. PT base is standard on the 90-,140- and 200-gallon single tank units and 60/60 and 100/100 combination tank units.

TW (Tow Only) Base

Tow operation. Pintle-eye hitch. Base is standard on the 300, 400, and 500-gallon single tank units and 150/150, 200/200, and 250/250 combination tank units.

PL (Push Lift) Base

Push/Lift – Three wheels. This base is unique to the 60-gallon Sump Shark. One swivel and two rigid casters help the Shark maneuver into tight spots. Fork pockets allow for pickup by fork lift.

PL6 (Push/Lift) Base

Hand push or fork truck transport. Six wheels, (two rigid and four swivel casters with 8” diameter x 2” phenolic roller-bearing wheels) for mobility in tight spaces. Longitudinal sleeves have two-way entry for fork truck transport.

PM (Pallet Mover) Base

Pallet truck engages swivel skid, raises to transport height and maneuvers Sump cleaner through narrow aisles and tight turns.

The CB1 Base customized sump cleaner transport to meet your plant’s needs.

The CB1 Base is a universal mount for use with industrial, walk/ride trucks, and 2 or 4-wheel trailers. The universal mounting base cradles the sump cleaner tank. The base is fitted with bolt flanges for easy installation on powered in-plant vehicles or trailers. The design permits a wide variety of handling options for large tank sump cleaners. Please call to discuss your transport needs.