CR

CF

W

CUT TRAMP-OILS UP TO 99% IN A SINGLE PASS

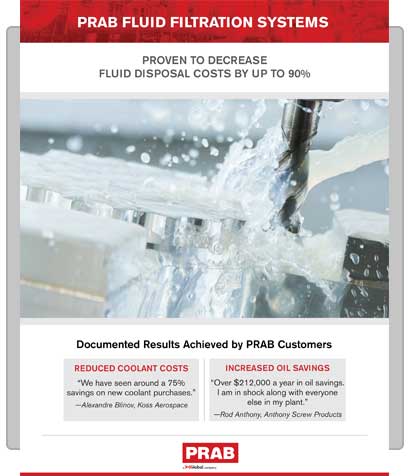

Remove free-floating and mechanically dispersed tramp oils, bacteria, slime, inverted emulsions, and more from individual machine sumps, central systems, and wash tanks. PRAB customers are seeing reduced new coolant purchases up to 75%, reduced waste volumes up to 90%, and a typical system payback in about six to nine months.

CR

CUT SPENT COOLANT DISPOSAL COSTS UP TO 90%

Remove up to 99% of tramp-oils and suspended solids from contaminated coolant. Continuous overflow process prevents odors and health issues caused by bacteria and rancidity. Recycle coolant at rates from 90 to 1,500 gph (341 to 5 678 lph). PRAB Guardian customers are seeing reduced new purchases up to 75%, and decreased spent coolant disposal costs up to 90%, and a typically system payback in six to nine months.

CR

EXTEND TOOL LIFE, ELIMINATE CHATTERING, REDUCE HEAT AND MATERIAL BUILDUP

A modular design makes this filter ideal for all types of machining centers. Feed fluid using an existing feed pump from the machine pump into bag filters for 10-micron filtration. High-pressure pump (1,000-PSI or higher) keeps fluid flowing back to machine at 14.5 gpm (55 lpm). Used to flush away chips, eliminate chattering, and reduce heat and material buildup. The resultant clean coolant extends tool life, too.

CF

REMOVE SOLIDS FROM ALL FREE-FLOWING INDUSTRIAL PROCESS LIQUIDS

Filter ferrous and non-ferrous metals, and organic or non-organic solids-such as glass, rubber, and plastic-perfect for grinding applications. PRAB paper bed filter customers are experiencing improved tool and coolant life. Disposable or permanent paper media produce a positive barrier suitable for low-to-medium stock removal.

CF

W

PRE-FILTER FERROUS MATERIALS FROM PROCESS LIQUIDS

Automated self-cleaning systems have been proven to minimizes maintenance and are perfect for grinding applications. The filtering surface is automatically indexed, only when necessary. Standard units are available with flow rates up to 250 gpm (946 lpm).

CF

W

ELIMINATE CONSUMABLE MEDIA AND MINIMIZE MAINTENANCE

Remove solid particulate away from liquid with centrifugal separation. No filters or consumable media and no special pumps for feed or discharge are required. Easily removable bowl for simple clean up and maintenance. Use as a stand-alone unit or incorporate into a custom-engineered filtration system and achieve flow rates up to 50 gpm (189 lpm). PRAB centrifuge customers are achieving improved tool life, better surface finishes, and reduced machine downtime and waste disposal.

CF

ELIMINATE CONSUMABLE MEDIA AND MINIMIZE MAINTENANCE

Remove solid particulate away from liquid with centrifugal separation. No filters or consumable media and no special pumps for feed or discharge are required. Easily removable bowl for simple clean up and maintenance. Use as a stand-alone unit or incorporate into a custom-engineered filtration system and achieve flow rates up to 50 gpm (189 lpm). PRAB centrifuge customers are achieving improved tool life, better surface finishes, and reduced machine downtime and waste disposal.

CF

CR

W

CLARIFY AND HANDLE INDUSTRIAL FLUIDS-EVEN ON A SMALL SCALE

Priced within reach of most small shops, sump cleaners provide high volume pumping capacities for a wide-range of applications.

PROVIDE CONSTANT BACTERIAL CONTROL

The natural choice for eliminating coolant rancidity. Generate and inject ozone directly into coolant for safe and effective bacteria control. Kills fungus and mold, and eliminates coolant sump odors. Applications include water, soluble oils, semi-synthetic coolants, synthetic coolants, and alkaline cleaners.

LOWER PRODUCTION AND MAINTENANCE COSTS

Eliminate high sludge volume produced in machining centers and grinding applications. Systems use disposable media to maximize contaminant removal. The vacuum chamber draws dirty coolant through the disposable filter media—applying the proven principle of optimal filtration through contaminate or sludge build-up, maximizing filtration as caking builds up on the media. Standard vacuum filter units are available with flow rates up to 3,000 GPM.

ELIMINATE DISPOSABLE MEDIA AND IMPROVE SURFACE FINISH UP TO 27%

Removes fine particulate down to 10 microns with synthetic filter media to reduce operational costs. Back-flushing keeps the semi-permanent media clean without using large volumes of air. Solids drop from the filter element and settle into a tank where they are removed by an automatic chain drag-out. PRAB Mon-a-Matic customers experience extended tool life and improve surface finishes. Send us your specifications and we’ll customize your unit to the size, capacity, and flow rate you need.

CUT OILY WASTEWATER VOLUMES UP TO 98%

Extend the life of wash and rinse water, while helping to meet zero manifesting goals and comply with federal RCRA requirements, as well as state and local discharge regulations. Separate emulsified oils and suspended solids from wastewater and coolant using hollow fiber, tubular, or spiral-wound membranes. Skid-mounted or fully automated systems are available. Modular design ensures easy expansion as business grows. PRAB Ultrafiltration customers have experienced reduced oily water volumes by as much as 98%, and decreased chemical additive usage up to 75%. Mini-UF and Ultra Mini-UF Systems are also available for small volumes of oily wastewater.

W

CR

CUT OPERATIONAL COSTS AND COMPLY WITH TIGHTENING REGULATIONS

Reduce water consumption, cut operating costs, and comply with tightening federal, state, and local wastewater treatment, handling, and disposal regulations. EVALED evaporators operate as closed loop systems under vacuum. One inlet and two discharge streams-concentrate and distillate. No air emissions ever!

W

CR