In a report issued during the 2018 National Safety Council Congress & Expo, the Campbell Institute-a respected global thought leader on placing environment, health, and safety at the core of business vitality-recommended that strategies designed to minimize serious injuries and fatalities in the workplace should include identifying the precursors to such events. By doing so, companies could focus on pre-emptively eliminating the potential for dangerous incidents to occur, rather than reacting to them after the fact.

Preventive measures such as these—in addition to regulatory compliance and fear of catastrophic consequences, both human and financial—are likely why the U.S. workplace is getting safer, according to the report Serious Injury and Fatality Prevention: Perspectives and Practices. The gains in safety are illustrated by the total recordable incident rate, which dropped to 3.0 incidents per 200,000 working hours in 2016 from 8.5 incidents per 200,000 hours in 1993.1

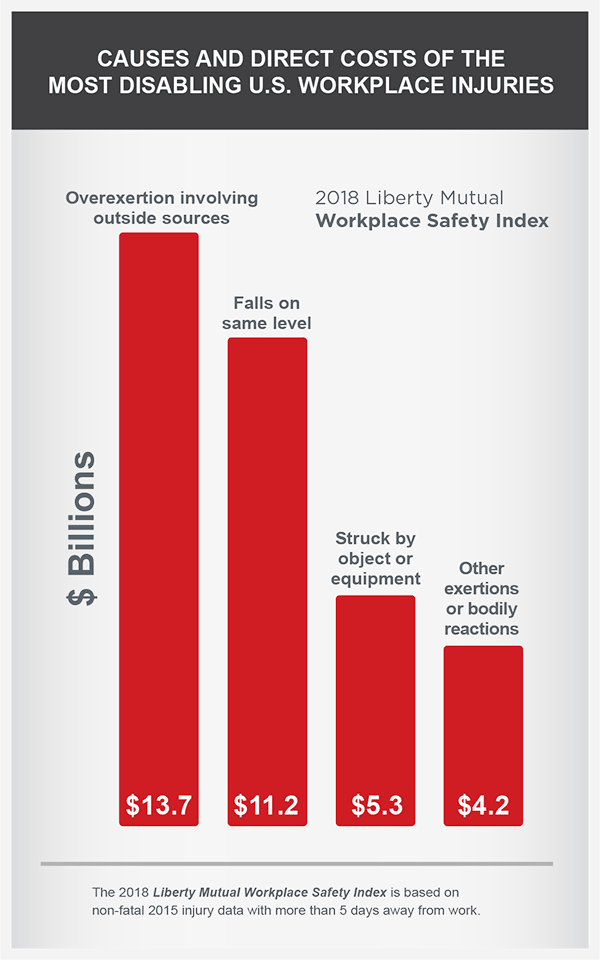

However, another report indicates that the cost of the most significant workplace injuries is actually rising. The Liberty Mutual Workplace Safety Index is an annual ranking that helps employers improve workplace safety by highlighting the financial impact and encouraging them to devote resources to eliminating the leading causes of work-related injuries and illnesses. The number of the most serious workplace injuries and illnesses fell by 1.5 percent between the 2017 and 2018 reports, while their cost—the total of medical and lost-wage payments-increased by 2.9 percent to more than $1 billion a week.2

While the first statistic in those findings is encouraging, the second one indicates that employers still have a long way to go in order to reduce the financial implications of an unsafe workplace. The metalworking industry is by no means an exception to this rule.

Every manufacturing plant, machine shop and metalworking facility should consider workplace injuries to be a significant detriment to profitability and overall sustainability. The environment that inherently exists in most if not all of these operations lends itself to a variety of occupational hazards. Four of them can be found among the Top 5 Causes and Direct Costs of the Most Disabling U.S. Injuries in the 2018 Liberty Mutual index2.

The potential for any or all of these incidents to occur exists in several workplaces, but it increases significantly in an industrial manufacturing plant. Larger operations typically generate pounds of metal chips, shavings, grindings and turnings for every metal part they machine. In the process, they also use large amounts of heavy-flow flood coolant to facilitate faster cutting and send the scrap material away from the tool. Factor in the number of parts a high-volume operation machines per day, with scrap and coolant ending up on the shop floor, and it’s easy to see how cluttered, wet walking surfaces can present a problem.

Back strains, joint sprains, cuts, bruises and other musculoskeletal conditions resulting from employees manually handling, pushing or lifting heavy loads of sharp scrap metal.

Slips, trips and falls on floors that are saturated with spent coolant and cutting oil, which was designed to maintain and prolong the life of machine tools.

Being struck or killed while operating or working in proximity of a forklift truck, equipment that spares workers the task of lifting heavy loads but brings its own set of hazards to an operation.

Asthma, hypersensitivity pneumonitis (an allergic type of pneumonia) and other lung diseases involving the immune system that can result from occupational exposure to metalworking fluids.3 Additional ailments can include dermatitis and cancers of the pancreas, larynx, skin and bladder.4

All of these possible outcomes make it clear that scrap metal and spent coolant must be removed from the point of production and dealt with as quickly as possible. To reduce occupational hazards in industrial operations that are largely automated, it is also imperative to automate the chip and fluid management process with scrap processing equipment, fluid recycling systems, and conveyors.

For optimal chip processing, metal scrap must be in the form of flowable chips. To reach this point, long turnings produced from milling, screw machines, swiss machines, drilling and other metalworking operations must go through a crusher or shredder. This allows employees to operate in safer work areas by reducing the volume of metal scrap to flowable chips, which minimizes exposure to sharp scrap edges.

This equipment compresses metal chips, loose turnings and swarf into near-solid, dry briquettes for recycling or feeding to furnace. These scrap pucks are easy to re-melt, transport or store, giving an operation more floor space, optimized container fill, more value from the scrap dealer and a cleaner, healthier, more environmentally friendly workplace.

Wringers or centrifuges remove cutting fluid from chips. This helps to eliminate run-off from wet chips that can spill onto the shop floor, creating slippery walking surfaces for operators.

Disposing of hazardous grinding swarf or filter cake can be difficult, expensive and create dangerous working conditions if the liquid within it is not separated from the scrap. In addition, due to its high surface area, swarf composed of some reactive metals can be highly flammable. Swarf stored in piles or bins may also spontaneously combust, especially if the swarf is coated with cutting oil. A horizontal screw press can process material that is 40-50% wet with coolant or cutting oils to localize and remove up to 85% of the fluid, minimizing fire hazards and keeping floors from becoming saturated and slippery.

Centralized systems are available that remove tramp oils and suspended solids from contaminated coolants. This equipment helps control bacteria and minimizes employee exposure to lubricants that can cause health problems and lead to expensive medical claims.

This equipment extends the life of soluble oils, coolants and washwater by removing free-floating and mechanically dispersed tramp oil from individual machine sumps, central systems and wash tanks. Tramp oil contributes to bacterial growth, which lowers the pH of the fluid and turns it into hazardous waste at the time of disposal. Removing it can minimize the possibility of respiratory and dermatitis issues occurring in plant employees. METAL SCRAP PROCESSING EQUIPMENT By reducing metalworking scrap to flowable chips and separating chips from spent fluid for recycle or reuse, an operation can increase productivity, get more value from its metal scrap, and use less floor space for moving and storing this material. But perhaps the most important benefit is creating a cleaner, safer working environment. Scrap metal processing equipment that contributes to workplace safety includes:

The simplest and most versatile solution for most metalworking operations, this equipment can handle most types of wet or dry metal scrap, from bushy material to chips and turnings, in a wide variety of conveyor paths. These conveyors can also move a high volume of material consistently, even in piles and high surges, decreasing forklift traffic and scrap contact with operators.

This equipment features a belt surface that prevents scrap from sticking to the belt while pivoting hinges flip scrap into a hopper. A seamless one-piece pan collects oily fluids and keeps them off the plant floor to reduce housekeeping headaches while improving employee safety and productivity.

Designed for conveying and elevating the most difficult, most abrasive, wet or dry materials in severe-duty situations, this equipment can be installed at floor level for easy transfer of material from the machine table to the conveyor. Like steel belt conveyors, drag conveyors also contribute to reducing forklift traffic and manual handling of potentially dangerous material.

These conveyors transfer all types of metal chips, fines and turnings, wet or dry bushy wads, and tramp metal solids with time- and energy-saving efficiency. Their liquid-tight trough construction makes them ideal for high-volume coolant flow applications, and their in-floor orientation allows both material and coolant to run directly into the conveyor with minimal manual interaction or slowdown of the process.

Vibrating scrap handling systems are the top choice for transferring hot, dry or wet abrasive metal scrap, chip processing or moving finished parts across horizontal distances. This equipment offers another safe alternative to forklift trucks while helping employees avoid injury from handling dangerous material.

The liquid-tight, leak-proof construction of these positive discharge conveyors allows them to prevent 100% of slippery cutting fluids from reaching the shop floor as they transfer all forms of scrap to its destination.

Metalworking operations that process large volumes of scrap metal and spent fluids need to minimize the dangers associated with handling those materials. It has been established that:

Automated conveying, scrap processing and fluid recycling systems are designed to quickly and efficiently remove considerable loads of scrap metal and spent fluids from core operations and transfer them to where they can be safely processed, disposed of or recycled. It is critical to understand and assess the advantages of each available system as they apply to a specific operation. It is also beneficial for metalworking operations to seek the assistance of a trusted, experienced supplier that can help them select the best solution for their specific needs, achieve the greatest return on their investment and maintain the safest possible workplace.

Mike Hook is the Sales & Marketing Director for PRAB and has more than 15 years of mechanical design and application experience. PRAB is a leading manufacturer of engineered conveyors and equipment for processing turnings, chips and metalworking fluids. PRAB also designs and builds industrial wastewater recycling systems.

1 Cision PR Newswire, The Campbell Institute Examines the Next Level of Workplace Safety – https://www.prnewswire.com/news-releases/the-campbell-institute-examines-the-next-level-of-workplace-safety-300736542.html

2 Cision PR Newswire, Workplace Injuries Cost U.S. Companies Over $1 Billion Per Week – https://www.prnewswire.com/news-releases/workplace-injuries-cost-us-companies-over-1-billion-per-week-300644539.html

3 ScienceDaily, Workplace Exposure to Metalworking Fluid May Cause Irreversible Lung Disease – https://www.sciencedaily. com/releases/2015/09/150928082147.htm

4 MCR Safety, Safety Tips for Metalworking Around Lubricants Greases and Coolants – https://www.mcrsafety.com/blog/safety-tips-for-metalworking-around-lubricants-greases-and-coolants