When Ogura Corporation, a Detroit based parts manufacturer, was faced with the dilemma of excessive coolant consumption, PRAB’s Fluid Filtration division was able to offer the optimal solution: Coolant Recycling.

Ogura’s primary business activity is the manufacture of air conditioner parts for the automotive industry. One of their major customers is the Ford Motor Company. Most of the machining done by Ogura is accomplished with CNC turning centers. Ogura’s coolant of choice is Trimsol, a water soluble coolant. Naturally, the machining of parts requires the use of large amounts of coolant, and coolants tend to adhere to chips as well as the machined parts. Over time water soluble coolants tend to decompose and become rancid. With this in mind, Ogura’s estimated use of make-up coolant was approximately two to three barrels per month.

Ogura would typically haul away used coolant almost every six months. Sometimes, it would be done sooner. Hauling times usually depended on when the rancidity levels became extreme. This practice became expensive and was not efficient. Ogura soon realized that a coolant recycling system could be used to extend the useful life of its coolant and reduce the amount of make-up coolant required.

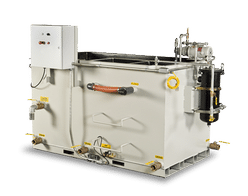

PRAB proposed the use of the Guardian HG-800 Coolant Recycling System with integral coolant return. Since Ogura had multiple machines which were located throughout the shop, PRAB also proposed the use of the HSC-175 Sump Cleaner.

The HG-800 uses a topped-off batch type process to recondition metalworking coolants. The Guardian has a central fluid collection point for tramp-oil and suspended solids removal, bacteria control and fluid concentration adjustment. A divided tank is used to process used coolant. The inlet (dirty coolant) compartment allows settling and removal of suspended solids. The second (clean coolant) compartment holds the clarified coolant. Three principles – gravity settling, filtration, and coalescence – are used to attain exceptional clarification of the coolant.

The unique advantage of the Guardian recycling system is that the clarified and refortified coolant continually overflows into the inlet compartment for further clarification. This feature provides continuous mixing of the clarified coolant, prevents rancidity, and assures that continuous volumes of clean coolant are ready for use.

After the incorporation of the HG-800 coolant recycling system into Ogura’s operations, make up coolant usage went from two to three barrels of coolant per month to just one barrel or less per month. In the first 12 months after installing the PRAB Guardian recycling system Ogura did not need to haul away any coolant.

For more than 60 years, PRAB has been developing material handling and chip and fluid management solutions that keep businesses moving in the right direction by adding value to scrap metal and reclaiming and recycling fluids. That’s why you’ll find thousands of PRAB installations in the world’s leading OEMs and suppliers. Each installation is an engineered solution to specific conveyance needs. For more information on PRAB, visit www.prab.com