Reduce or Eliminate

- Smoke and mist in the air

- Bacteria in the coolant

- Coolant waste up to 90%

- New fluid purchases up to 75%

- Health risks from skin irritations

- Equipment breakdowns

Increase

- Tool life up to 25%

- Coolant life

- Parts washer bath life

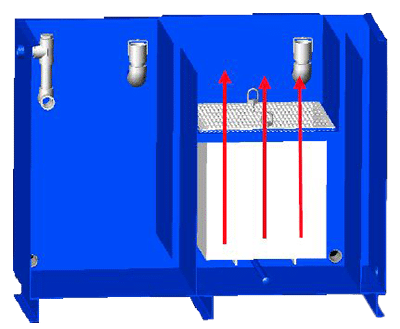

Removing tramp oils can be done using many different processes. However, the most effective method is coalescing. As part of the metalworking fluid recycling process, coalescing is a technique used to remove free-floating and mechanically dispersed tramp oils from spent cutting fluid using coalescing media. This media, located inside the recycling unit, attracts small droplets of oil until they come together (coalesce) forming larger droplets. Those drops rise to the next droplet and the droplet becomes even larger, rising to the top of a separator where they are removed by oil weirs.

When choosing the right coalescing system for the shop floor, there are differences in efficiency and time savings depending on the supplier, but for the most part many suppliers offer both machine side and centralized systems. Here are just a few of things to look at when choosing a coalescer (fluid recycling system):

- What type of media is used?

- What type of maintenance will the system require?

- Is the system self-cleaning?

- Is the system proven to be efficient at other metalworking operations?

- What is the proven payback time on the system?

PRAB’s Guardian™ Coolant Recycling System and Tramp Oil Separator use unique tellerettes and pall rings as the coalescing media which are in a media basket in a compartment of their filtration systems. The media in the Guardian and tramp oil separator is automatically cleaned daily using air sparging to eliminate manual cleaning—significantly reducing maintenance labor. In air sparging, small air bubbles are released under the media basket to scrub it clean and remove any oil-soaked solids that may have collected on the media.

Unlike PRAB, some fluid recycling equipment suppliers use stainless steel plates (coalescing plate packs) or other types of coalescing media which have a lower affinity for oil and therefore are not as efficient. They may claim that steel plates will not plug like PRAB’s media coalescers. However, a wide spacing is put between the plates to prevent plugging and that wide space allows larger oil droplets to pass between the plates which are then carried over into the coolant—decreasing efficiency. In addition, when the plate pack becomes plugged with solids they must be manually removed and cleaned. Because PRAB’s media is automatically self-cleaning daily, it eliminates the need to remove and manually clean the coalescing media.