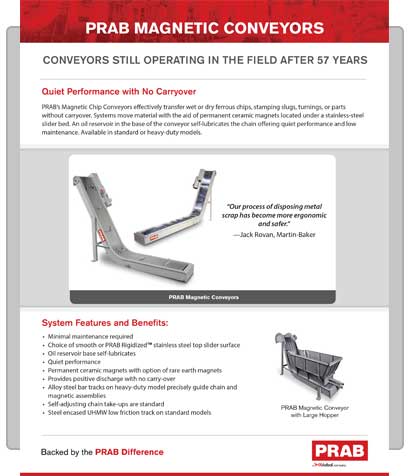

PRAB Magnetic Conveyors

Download Conveyors Still Operating in the Field After 57 YearsQuiet Performance with No Carryover PRAB’s Magnetic Chip Conveyors effectively transfer wet or dry ferrous chips, stamping slugs, turnings, or parts without carryover. Systems move material with the aid of permanent ceramic magnets located under a stainless-steel slider bed. An oil reservoir in the base of the conveyor self-lubricates […]