For operations dealing with phosphate baths, a centrifuge that can reliably clear sludge that is collected while also protecting equipment is invaluable. Although gravity bed filter systems are an effective option, PRAB’s Automatic Solid Bowl Centrifuge provides solutions to a variety of challenges that these operations may face during any given project.

When an application must reclaim coolant, cutting oil, wash water, rinse water, and wastewater fluids, equipment that requires disposable filter media is often used. Although effective, purchasing replacement filter media can be costly for operations that deal with phosphate baths. Properly disposing used media presents additional expense as well.

When zinc phosphates and steel interact during pretreatment baths, sludge can build up rapidly and cause problems related to equipment quality. One way to address this issue is by implementing some form of gravity bed filter system. Although this setup is effective for larger particles, it is not as effective at separating smaller particulates.

An additional concern that this approach presents is the cost of purchasing replacement filters. PRAB specializes in semi-automatic, automatic, and specialty centrifuges that do not use filters or consumables and feature few moving parts.

Typically, makeup water and chemicals are needed to replenish phosphate tanks. PRAB’s Automatic Solid Bowl Centrifuge keeps the filtration process internally contained, which prevents phosphate baths from making contact with the atmosphere. This helps steadily maintain the temperature of these baths. In turn, this greatly reduces the amount of water and chemicals that would typically be used to refill these tanks.

Typically, makeup water and chemicals are needed to replenish phosphate tanks. PRAB’s Automatic Solid Bowl Centrifuge keeps the filtration process internally contained, which prevents phosphate baths from making contact with the atmosphere. This helps steadily maintain the temperature of these baths. In turn, this greatly reduces the amount of water and chemicals that would typically be used to refill these tanks.

Draining the sludge from phosphate tanks can be an intensive process that takes many hours to complete. Oftentimes, production can be lost while this procedure is carried out.

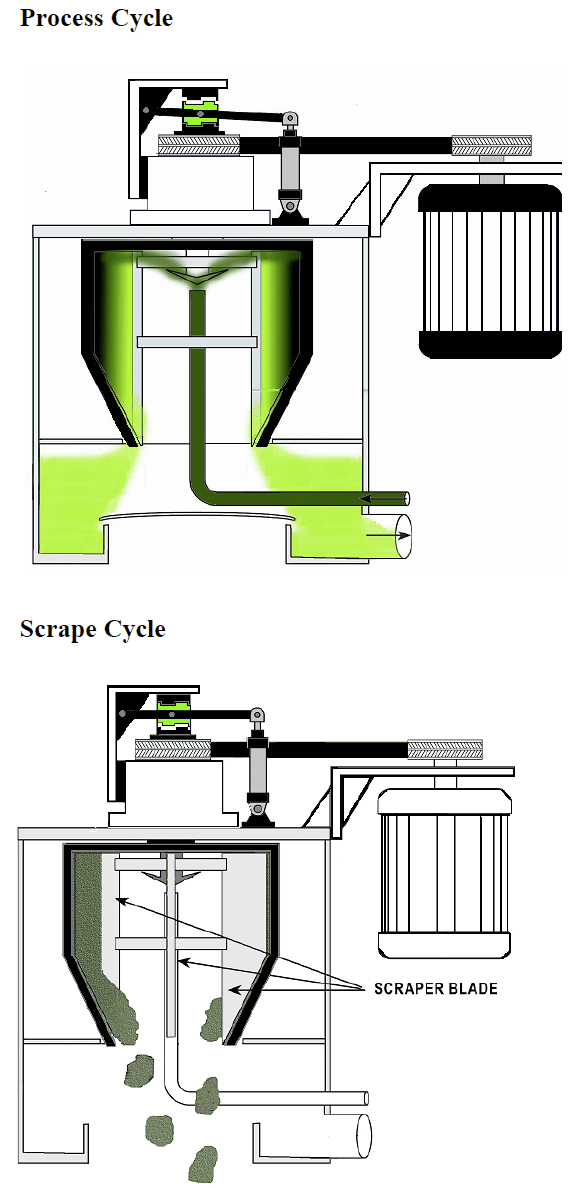

Lasting around 80-90 minutes, the filter cycle of PRAB’s Automatic Solid Bowl Centrifuge can be set to automatically pull sludge from alternate sides of the phosphate tank every 30 minutes.

The process includes stoppage of the centrifugal unit, disengagement of the clutch, and reversal of the motor to scrape accumulated sludge from the inside of the unit. From there, sludge drops into a hopper that is positioned under the unit.

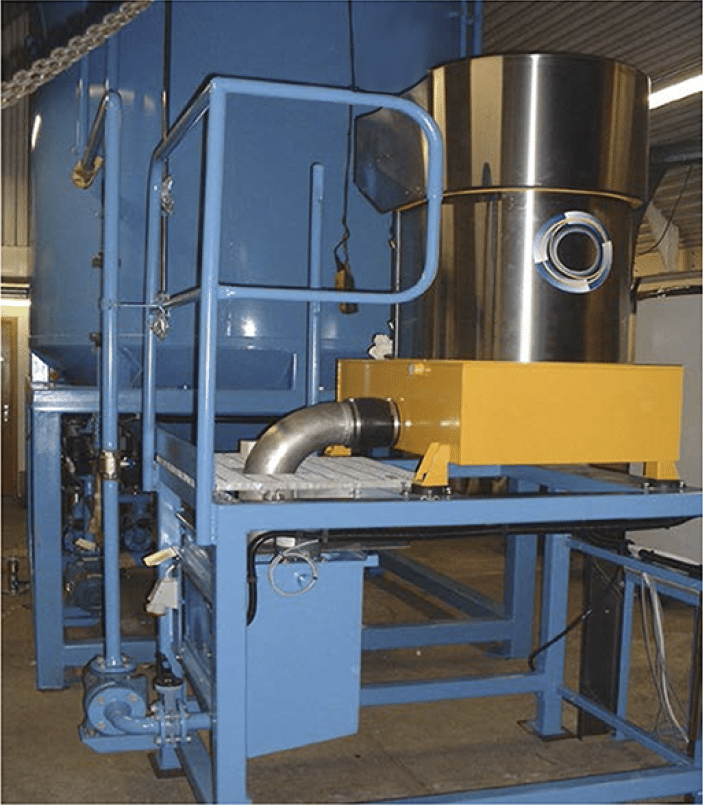

Thanks to its compact design, an added benefit of PRAB’s Automatic Solid Bowl Centrifuge unit is the minimal amount of floor space it occupies. The additional space that is freed up by this model could contribute to lessened foot traffic and allow for additional units to be installed.

An enterprise that utilizes phosphate baths understands how crucial it is to find and implement a centrifuge system that matches its requirements as an operation. By eliminating the need for disposable filter media, reducing the demand for large amounts of chemicals and makeup water, and cutting down on cleaning time, PRAB’s Automatic Solid Bowl Centrifuge is an efficient choice.

Tom Tripepi is the Fluid Filtration Technical Director for PRAB and has more than 40 years of industry experience.

PRAB is a leading engineer and manufacturer of conveyors, chip and fluid management systems, and industrial water and wastewater treatment equipment. Our customized solutions automate metal handling, reduce labor costs, reclaim and recycle expensive cutting fluids/coolants, and maximize return on recycling metals. With our expertise, honed by more than 4,500 installations for the world’s leading OEMs and suppliers, PRAB continuously improves material handling, housekeeping, and compliance to environmental rules and regulations within the automotive, aerospace, medical, electronics, defense, off-road, and energy markets. For more information, visit prab.com.