Fluid recycling systems utilize several different technologies to separate solid matter and contaminants from used metalworking fluids so that coolants and oils can be reclaimed for future use. The benefit of this process is a drastic reduction in new fluid purchases and improved working conditions for staff due to the bacteria that is eliminated.

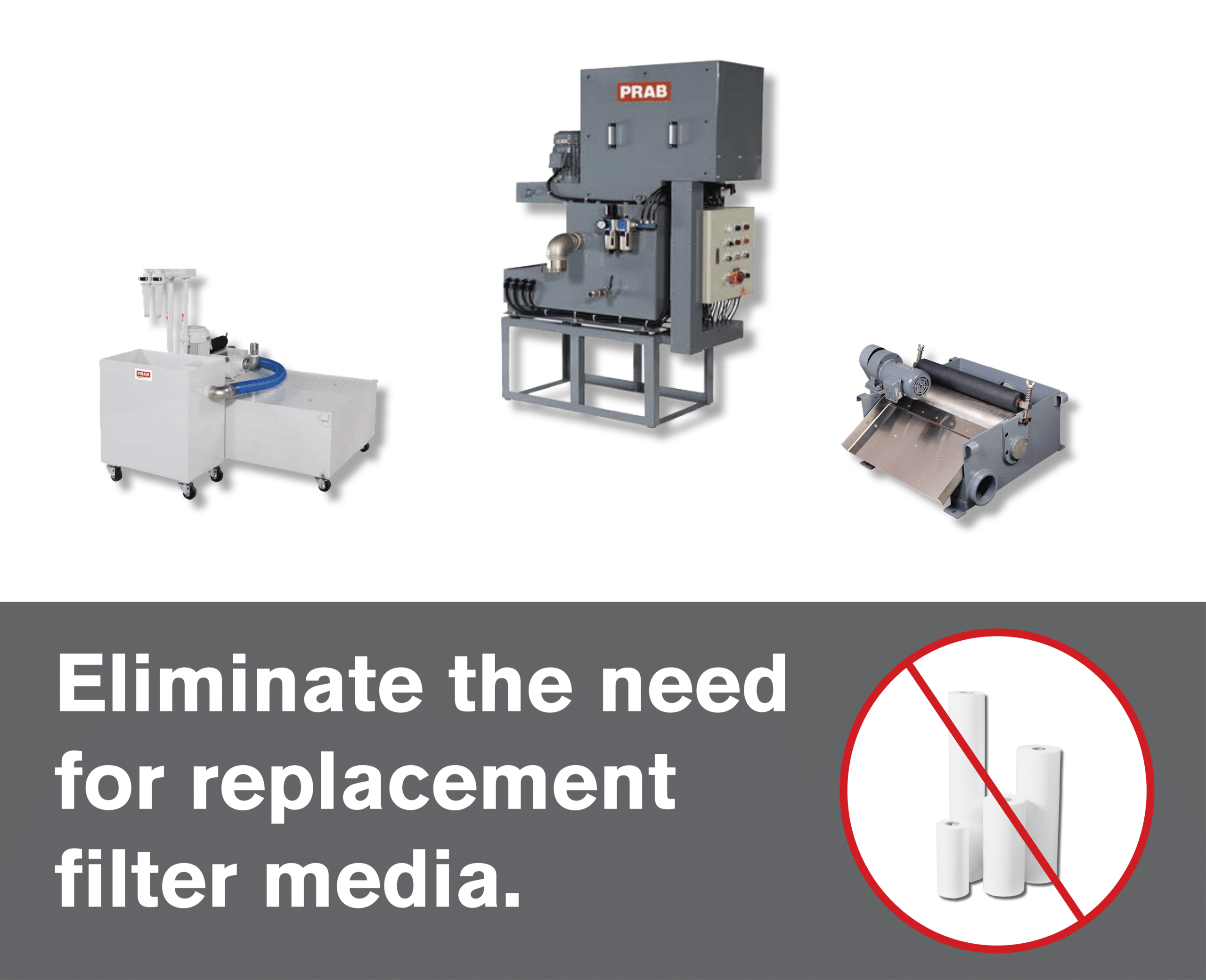

For certain equipment, filter media is needed for this separation to occur. As one can imagine, the costs to replace this media can add up rather quickly. Recognizing that this may pose a problem to a company’s budget, PRAB offers a selection of fluid filtration options that do not require filter media.

Safe to operate and easy to maintain, the hydrocyclone removes up to 98% of contaminants via ascending and descending vortexes in a cylindrical feed that removes contaminants from coolant without the need for filter media. Other benefits include improved grinding wheel performance, workpiece finish, and tool life.

The ferrous and non-ferrous materials a hydrocyclone can filter include:

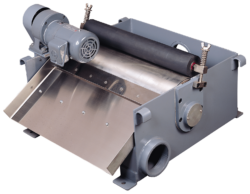

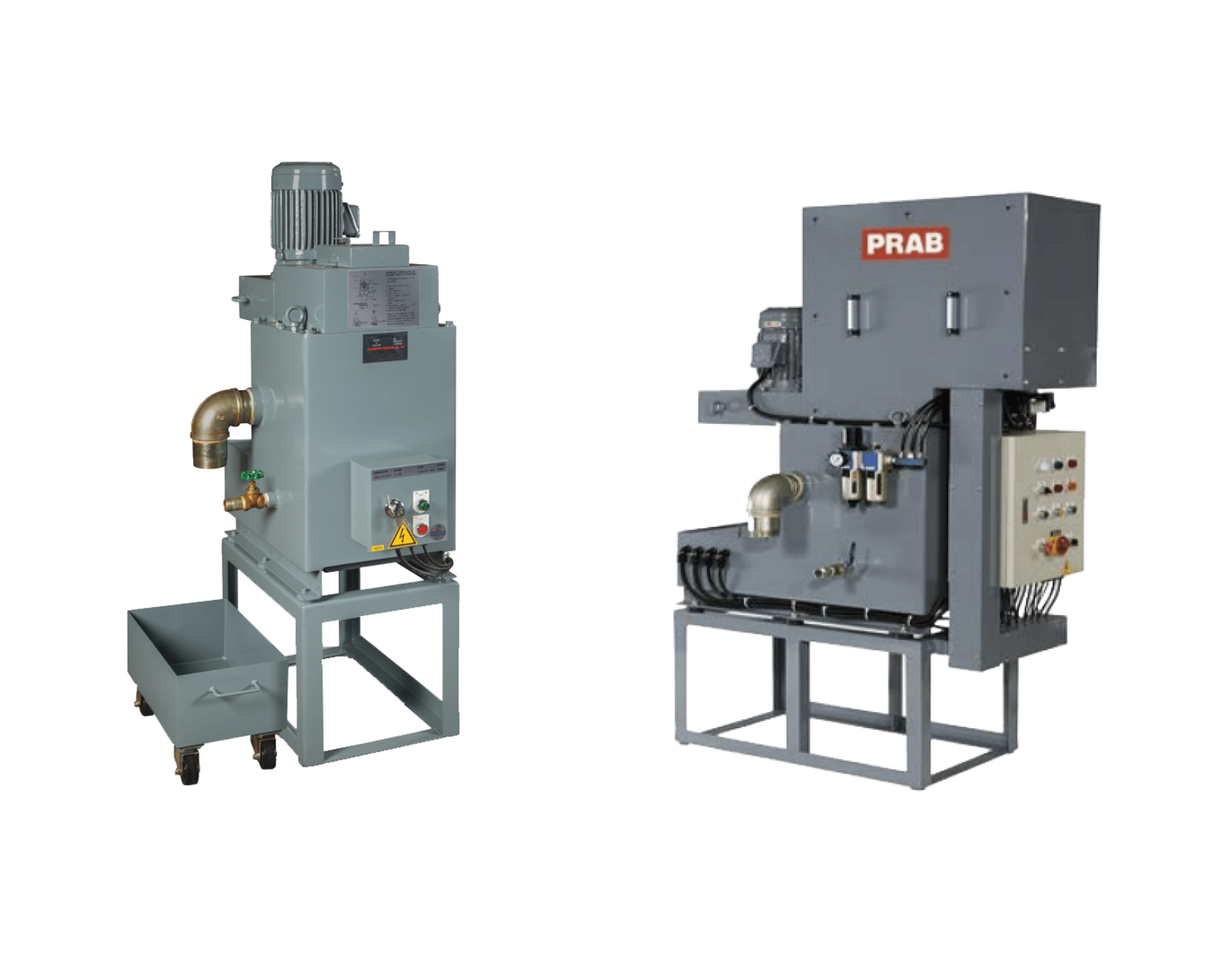

A magnetic separator is used as a pre-filter that is meant to limit contaminants from reaching subsequent industrial filtration equipment. It removes ferrous materials like sludge and chips from both water soluble and neat oils with high-intensity ferrite or rare earth magnets. Additional benefits include easy integration with paper bed filters, prolonged tool life, continuous operation, and improved surface finish of component parts.

Magnetic separator applications include:

Specifically engineered for heavy-duty applications, such as metal chip processing and industrial wastewater treatment, centrifuges separate solids from liquids where removal of fines is necessary for recycling or reuse. The PRAB industrial centrifuge is ideal for separating all types of ferrous and non-ferrous solids from oils and water-based coolant with flow rates of up to 50 gpm.

Centrifuge applications include:

Due to the costs associated with purchasing replacement filter media, investing in media-less fluid filtration alternatives can benefit an organization’s bottom line. As a manufacturer that specializes in custom-built solutions, PRAB’s fluid recycling product line guarantees customers a technologically superior solutions at affordable prices.