PRAB Pivot Belt™ Conveyor

Proven to Raise Productivity Up to 60%Customers are Experiencing Increased Productivity and SafetyPRAB’s Pivot Belt

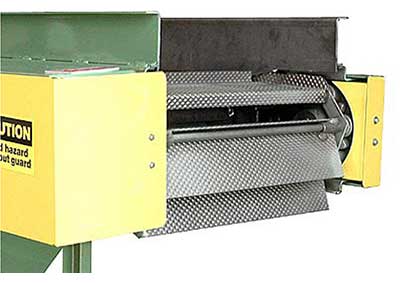

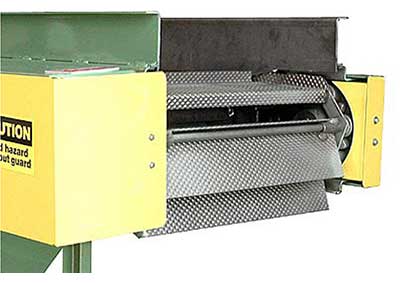

™ Conveyor with Rigidized™ belt surface prevents scrap from sticking to the belt, while exclusively designed pivoting hinges flip scrap effortlessly into your hopper. Raised pusher flights keep material moving while the seamless, one-piece pan beneath, collects oily fluids to reduce housekeeping and keep workers safe and more productive.

Features:

- Rigidized™, dimpled belt surfaces help to eliminate carry over of sticky, oily pieces

- Overlapping hinged pans pivot for positive discharge

- Raised pusher flights ensure a positive material flow

- Extended life with replaceable bushings in heavy-duty side chain

- Seamless one-piece pan construction for fluid accumulation

- Side-wings and flights are integrally die-formed with pan

- Heavy-duty side frames, track and wear bars for precise belt tracking and longer life

- Built-in automatic overload protection

System Benefits:

- Minimizes carryover of oily slugs, knockouts and thin gauge scrap

- Keeps plant floor clean and safe by collecting oily fluids in the seamless pan

- Torque-limiting protection shuts down the conveyor when loads becomes too heavy, preventing scrap handling equipment damage

“Our process of disposing metal scrap has become more ergonomic and safer.”– Jack Rovan, Martin-Baker

Backed by the PRAB Difference

Conveyors Still Operating in the Field After 57 Years

Options:

- Drive can be mounted above, below or on the side of the conveyor

- Custom skirts, chutes and hoppers to fit application requirements

- Special side sections are available for height-restricted areas

- Special support frames and casters

- Flanged rollers available on both 2-1/2” and 4” pitch

- Variable speed drive

Optional auto lube systems for automatic greasing of bearings. Auto lube systems are designed to automatically supply a small quantity of clean grease or oil to bearings on a regular basis- improving bearing performance and eliminating maintenance required for manual greasing.

Models and Configurations:

PRAB’s Pivot Belt Conveyors are available in 2.5” to 4” pitch, designed to convey materials ranging in various weights and bulk densities. Multiple configurations are available including Z-Style, L-Style, and Straight.

Z-Style

- Different elevation of discharge point

- For Filling of larger containers

- Used in overhead layouts

L-Style

- Different elevation of discharge point

- Used for feeding small containers

Straight

- Used in horizontal or inclined layouts

The Pivot Belt’s Rigidized™, dimpled surfaces help eliminate carry-over

The Pivot Belt’s Rigidized™, dimpled surfaces help eliminate carry-over Pivot Belt Conveyor hinges

Pivot Belt Conveyor hinges

Contact us to request a quote today