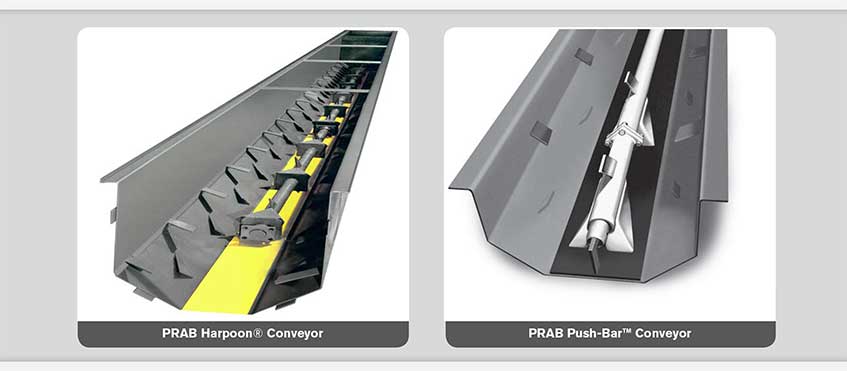

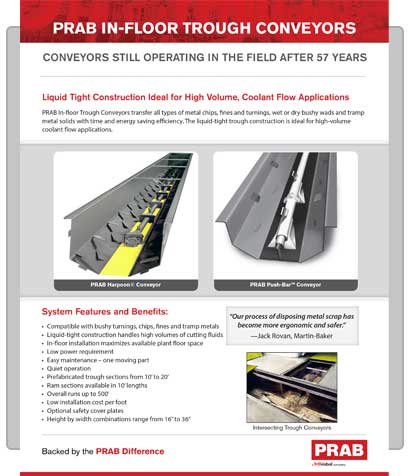

PRAB In-Floor Trough Conveyors

Conveyors Still Operating in the Field After 57 YearsLiquid Tight Construction Ideal for High Volume, Coolant Flow ApplicationsPRAB In-floor Trough Conveyors transfer all types of metal chips, fines and turnings, wet or dry bushy wads and tramp metal solids with time and energy saving efficiency. The liquid-tight trough construction is ideal for high-volume coolant flow applications.

System Features and Benefits:

- Compatible with bushy turnings, chips, fines and tramp metals

- Liquid-tight construction handles high volumes of cutting fluids

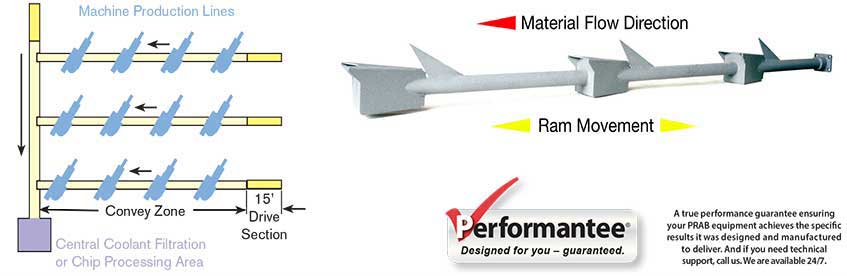

- In-floor installation maximizes available plant floor space

- Low power requirement

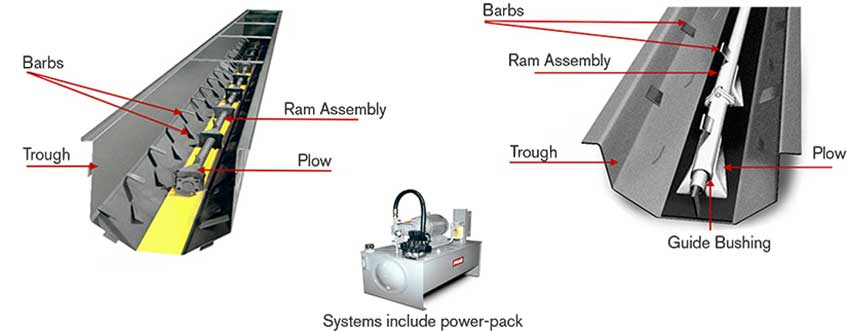

- Easy maintenance – one moving part

- Quiet operation

- Prefabricated trough sections from 10’ to 20’

- Ram sections available in 10’ lengths

- Overall runs up to 500’

- Low installation cost per foot

- Optional safety cover plates

- Height by width combinations range from 16” to 36”

“Our process of disposing metal scrap has become more ergonomic and safer.”– Jack Rovan, Martin-Baker

Backed by the PRAB Difference

Proven to Raise Productivity Up to 60%

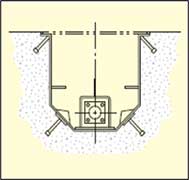

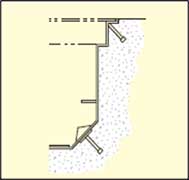

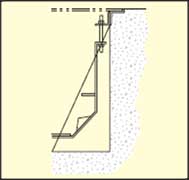

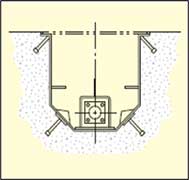

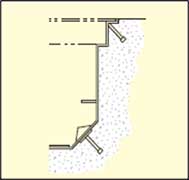

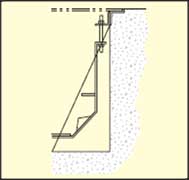

Cast-in-place

Cast-in-place

standard deck plate Cast-in-place

Cast-in-place

heavy-duty deck plate Suspended in pit

Suspended in pit Pit mounted

Pit mounted

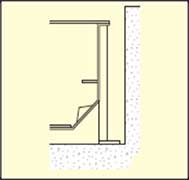

Trough Models:

Typical System Layout:

Contact us to request a quote today