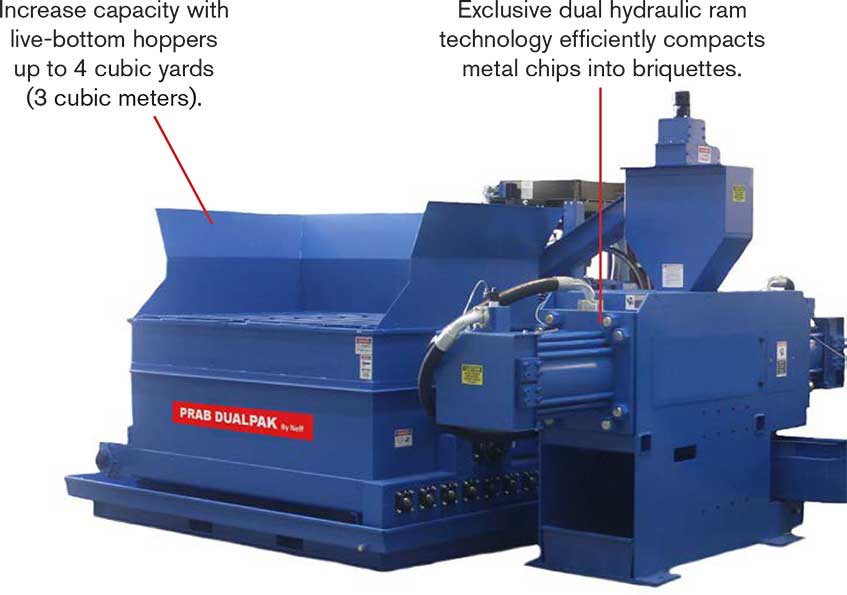

PRAB’s Dualpak™ Briquetter machines increase the value of metal chips, loose turnings and swarf by compressing them into near solid, dry briquettes to send to the recycler or feed to furnace. Unlike competing briquetting machines, the Dualpak uses two opposing hydraulic cylinders. These cylinders press metal equally from both sides, creating the industry’s densest briquettes.

“We get $0.17 per pound more for our briquetted material over loose chips.”– Jack Rovan, Martin-Baker Plant Manufacturing Manager

Choose the capacity you need from a variety of sizes. All models come pre-wired for easier, more flexible installation.

| Estimated Throughput (Ibs/hr): Aluminum, Steel, Cast Iron, Copper, Brass. System throughput is directly related to the bulk density of the incoming material. |

|||||||||

| Model # | MX20-15M | MX30-15M | MX30-20M | MX35-30M | MX35-40M | MX35-60M | MX50-60M | MX50-100M | MX70-250M |

| Briquette Diameter | 2″ | 3″ | 3″ | 3.5″ | 3.5″ | 3.5″ | 5″ | 5″ | 7″ |

| 7 Ibs/ft3 | 32 Ibs/hr |

63 Ibs/hr |

100 Ibs/hr |

150 Ibs/hr |

188 Ibs/hr |

250 Ibs/hr |

375 Ibs/hr |

500 Ibs/hr |

1,400 Ibs/hr |

| 14 Ibs/ft3 | 65 Ibs/hr |

125 Ibs/hr |

200 Ibs/hr |

300 Ibs/hr |

375 Ibs/hr |

500 Ibs/hr |

750 Ibs/hr |

1,000 Ibs/hr |

2,800 Ibs/hr |

| 21 Ibs/ft3 | 95 Ibs/hr |

188 Ibs/hr |

300 Ibs/hr |

450 Ibs/hr |

560 Ibs/hr |

750 Ibs/hr |

1,125 Ibs/hr |

1,500 Ibs/hr |

4,200 Ibs/hr |

| 28 Ibs/ft3 | 125 Ibs/hr |

250 Ibs/hr |

400 Ibs/hr |

600 Ibs/hr |

750 Ibs/hr |

1,000 Ibs/hr |

1,500 Ibs/hr |

2,000 Ibs/hr |

5,600 Ibs/hr |

| 56 Ibs/ft3 | 250 Ibs/hr |

400 Ibs/hr |

800 Ibs/hr |

1,200 Ibs/hr |

1,500 Ibs/hr |

2,000 Ibs/hr |

3,000 Ibs/hr |

4,000 Ibs/hr |

14,000 Ibs/hr |

| 84 Ibs/ft3 | 300 Ibs/hr |

625 Ibs/hr |

1,000 Ibs/hr |

1,500 Ibs/hr |

2,000 Ibs/hr |

2,500 Ibs/hr |

3,750 Ibs/hr |

5,000 Ibs/hr |

14,000 Ibs/hr |

| Mechanical & Electrical Specifications | |||||||||

| Motor Horsepower (main) | 15 HP |

15 HP |

20 HP |

30 HP |

40 HP |

60 HP |

60 HP |

100 HP |

250 HP |

| Main Hydraulic Pump Flow | 22 GPM |

23 GPM |

48 GPM |

56 GPM |

60 GPM |

98 GPM |

98 GPM |

141 GPM |

168 GPM |

| Total Force Available | 42 tons |

106 tons |

144 tons |

144 tons |

144 tons |

144 tons |

295 tons |

295 tons |

577 tons |

| Operating Pressure | 3,000 psi |

4,219 psi |

4,219 psi |

3,675 psi |

3,675 psi |

3,675 psi |

3,827 psi |

3,827 psi |

3,500 psi |

| Standard Face Pressure | 27,000 psi |

30,000 psi |

|||||||

| Cylinder Bore Size | 2 @ 6″ | 2 @ 8″ | 2 @ 8″ | 2 @ 10″ | 2 @ 10″ | 2 @ 10″ | 2 @ 14″ | 2 @ 14″ | Consult Factory |

| Power Required | |||||||||

| Machine Full Load Amps | 22.5 amps |

22.5 amps |

34.4 amps |

46.9 amps |

59.4 amps |

84.4 amps |

84.4 amps |

134.4 amps |

345.8 amps |

| Infeed Hopper | 4 Yard Live Bottom Hopper | ||||||||

Augers feed chips into a compression chamber, then two opposing hydraulic cylinders press the metal, squeezing out any fluid and creating a compact puck. System is available with 1,2,3, and 4 cubic yard live bottom hoppers and can also be adapted to compress swarf.