PRAB Diagonal-Shaft Wringer

Download

Proven To Increase Scrap Value Up To 25% Reclaim up to 98% of Valuable Coolant and Cutting Oils

Cut your fluid costs and make your scrap worth more. PRAB’s heavy-duty wringers/centrifuges use more than 600G’s of force to reclaim up to 98% of the valuable coolant and cutting oils from aluminum, brass, cast iron, steel, stainless steel and other metal chips. This allows you to reclaim fluids for recycle and reuse, significantly reduce haul-away cost, and get more value from dry chips.

Backed by the PRAB Difference

Top Features & Benefits:

Increase recycling value of scrap: aluminum, brass, cast iron, steel, stainless steel and alloys.

Minimize maintenance downtime with exclusive reversing feature on CD models only.

Reuse and lower your hazardous waste disposal costs.

Models available in 16” (40 cm), 24” (61 cm) and 40” (101 cm) diameters.

PRAB Diagonal-Shaft Wringer Get A Higher Payback From Your Scrap Metal

PRAB 24CD Wringer System PRAB 24CD Wringer System

PRAB 24AD Wringer System PRAB 24AD Wringer System

Contact a chip system product specialist today

PRAB 24CD Crusher/Wringer System

Minimize Maintenance & Haul-Away Costs

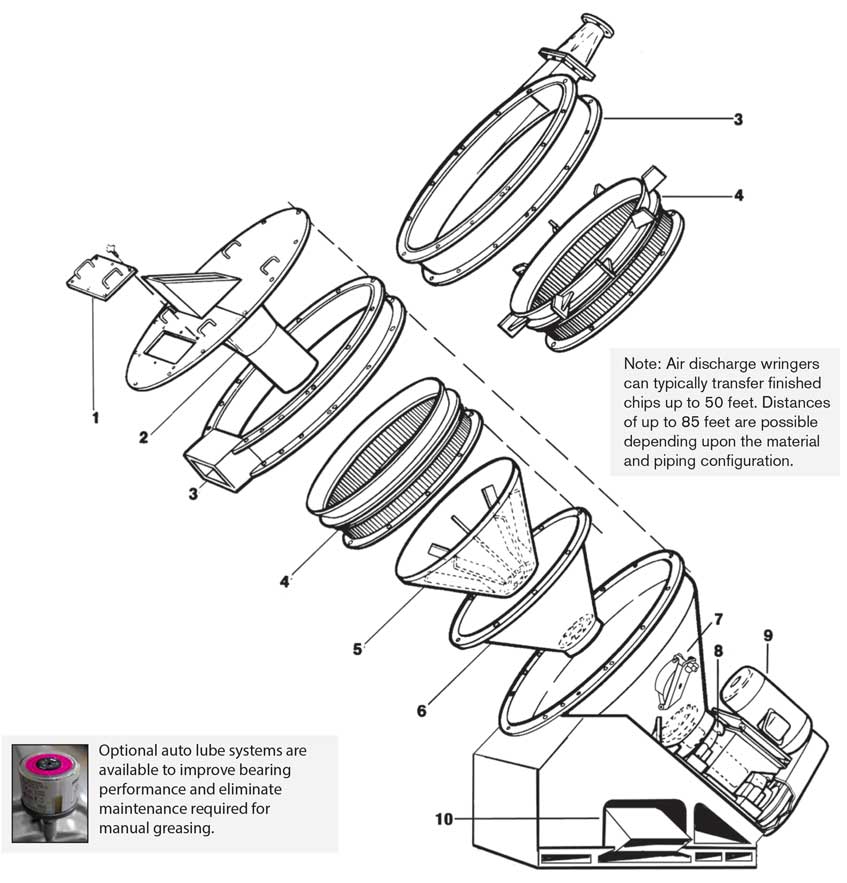

Standard Components:

Access plate

Feed chute (abrasion resistant steel)

Impact Ring (manganese steel)

Bar screen (stainless steel) in 16”, 24” and 40” diameter with paddles (AD model) or without paddles (CD Model)

Bowl liner (easily replaceable)

Bowl (spun steel)

Inspection hatch

Heavy-duty bearings (standard, off-the-shelf)

Motor (standard, off-the-shelf)

Fluids discharge

Get a Higher Payback from Your Scrap Metal

Model #

16-CD

24-CD

24-AD

40-CD

40-AD

Motor Power

7.5 hp

10 hp

15 hp

20 hp

30 hp

Nominal

20 ft3/hr

100 ft3/hr

70 ft3/hr

160 ft3/hr

115 ft3/hr

Bar Screen

16”

24”

24”

40”

40”

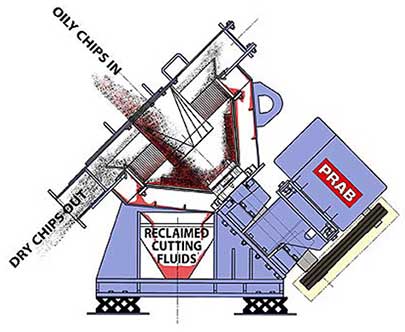

Illustration of chip and fluid flow using the gravity discharge model. Nominal Throughput (lbs/hr)*

Unit

Steel or Stainless

Brass

Aluminum

Cast Iron

24AD

3,000

3,000

2,000

N/A

24CD

4,000

4,000

2,500

5,000*

40AD

6,000

6,000

3,000

N/A

40CD

8,000

10,000

4,000

10,000*

*Throughput dependent on incoming bulk density

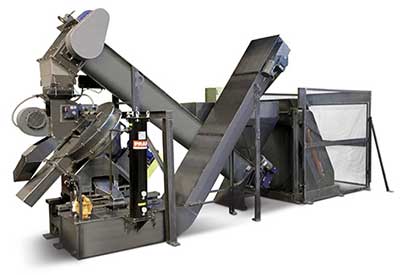

Wringer can be integrated with other PRAB equipment for a complete chip processing system. PRAB’s E-Series Chip System is a smaller self-contained system for lower volume applications.