How Vacuum Evaporation Can Lower Multi-Stream Wastewater Treatment Expenses

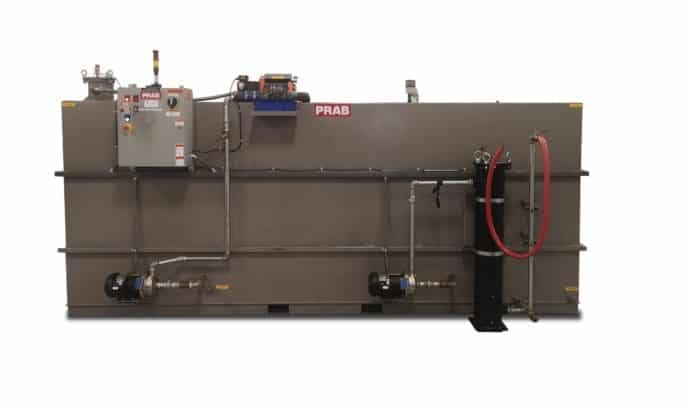

Treating industrial multi-stream wastewater is a complex and expensive endeavor for many commercial operations. The high flow rates associated with multi-stream wastewater have traditionally required costly, sprawling treatment systems that occupied a lot of precious floorspace and consumed energy. Fortunately, using vacuum evaporation and distillation technologies as part of a comprehensive treatment system addresses these issues. With that in mind, […]