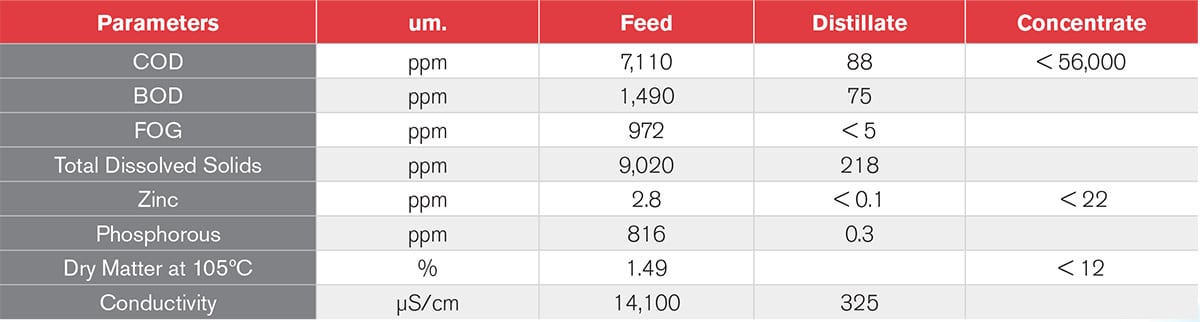

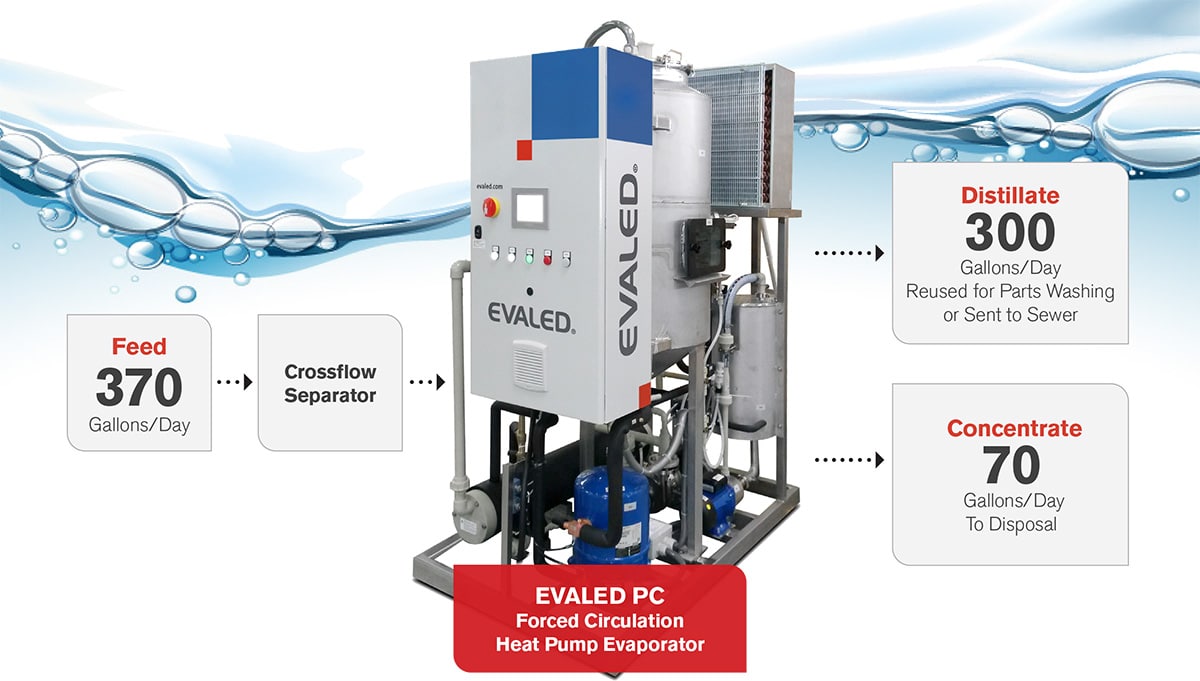

Bendix Commercial Vehicle Systems, LLC needed a wastewater treatment technology that would treat alkaline cleaner and alkaline cleaner rinse water. They use an RO System to treat the incoming city water to reduce the conductivity because high conductivity in the wash and rinse waters negatively effects the processing of parts after the washer.

Bendix Commercial Vehicle Systems, LLC

Bendix Commercial Vehicle Systems, LLC is a global manufactur-er of leading-edge active safety technologies, engine dampeners, and components for medium and heavy-duty vehicles throughout North America.

Bendix Commercial Vehicle Systems, LLC needed a wastewater treatment technology that would treat alkaline cleaner and alkaline cleaner rinse water. They use an RO System to treat the incoming city water to reduce the conductivity because high conductivity in the wash and rinse waters negatively effects the processing of parts after the washer.

The Distillate coming from the PC F 1.4 AA is very clean and the conductivity so low it gets added directly to the RO Permeate tank and is reused for make-up water in the wash and rinse tanks.

The main goal was to produce a very clean effluent that would enable the company to meet POTW discharge limitations and from a sustainability perspective allow for water reuse with a low carbon footprint. The solution also needed to minimize daily maintenance, be automated, energy efficient, and be compact in size.

The main component of the solution that PRAB supplied to Bendix Commercial Vehicle Systems, LLC was an EVALED PC F 1.4 AA Forced Circulation Evaporator. This vacuum distillation technology system was designed to treat low to medium waste-water flow rates and produce maximum distillate quality. The PC F Series Evaporators range from 185-6,340 gallons/day of distillate production. The system also included an equalization tank, solids filtration, tramp oil separator, process pumps, and fully automated controls. This allows distillate to be returned to the parts washing application.

Matching the application and material was critical to selecting an evaporation technology that provides superior reliability. The PC heat pump evaporator’s forced circulation and low boiling temperature minimize scaling, fouling, and corrosion. The system produces no air emissions and has low energy consumption. The automated system includes PLC controls and is designed for continuous operation with minimal supervision.

• Met POTW Discharge Limitations

• Sustainability; 81% Reuse of Wastewater

• Low Maintenance and Automation for Ease of Use