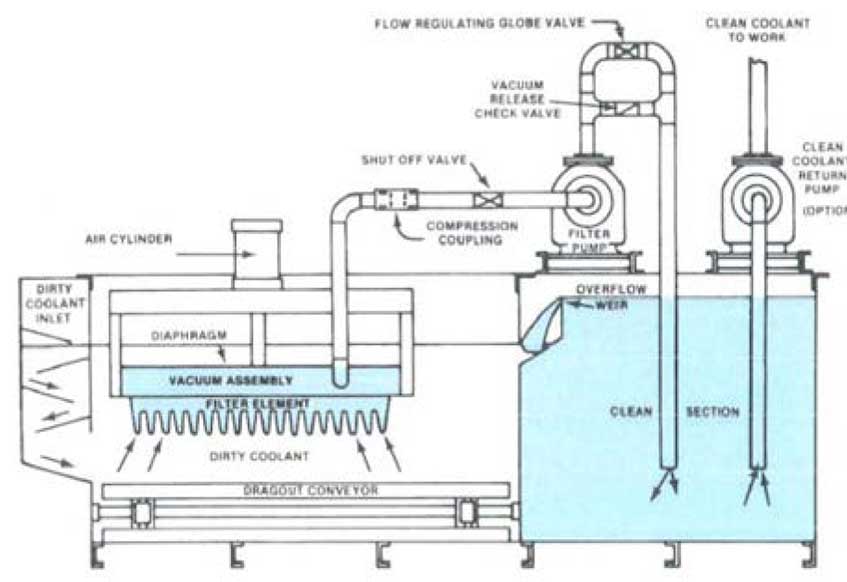

PRAB’s Mon-A-Matic™ semi-permanent media vacuum filter uses a synthetic filter media to reduce operational costs while providing fine particulate removal.

System Features:

Top Benefits:

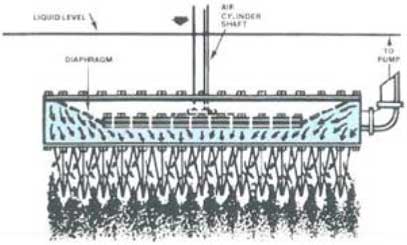

Mon-A-Matic™ System Operation:

Contaminated liquid enters the system through a specially designed inlet and is then held in a process tank. Heavy contaminants settle to the bottom of the tank and are removed via a drag-out conveyor. Suspended inside the tank are filter media manifolds. Vacuum pressure draws liquid through the filter media holding the particulate on the surface. Only clean liquid is allowed to pass through the media and into a clean process tank for return to the machining or grinding operations.

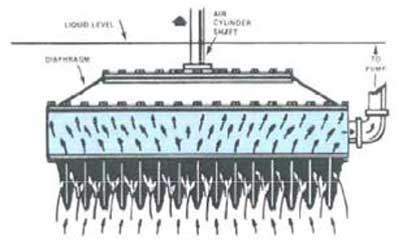

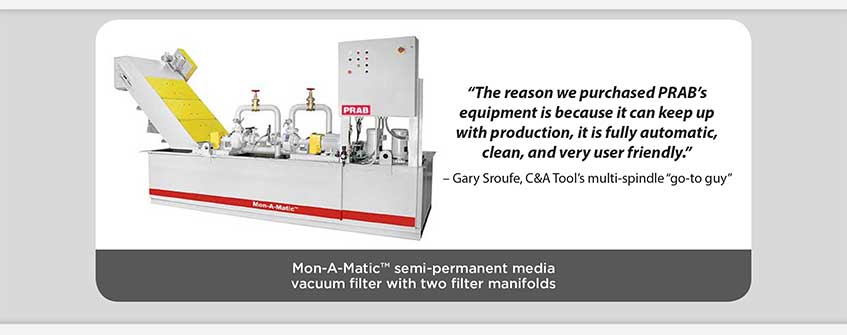

The system automatically senses when the filter media needs cleaning and performs a back-flush cycle. It then performs a back-flush cycle. Clean liquid is forced (via an air cylinder and diaphragm) through the filter to dislodge the filter cake. The filter cake then settles to the bottom of the process tank where it is removed by the drag-out conveyor. After the backflush cycle is completed, the filtering process will resume.