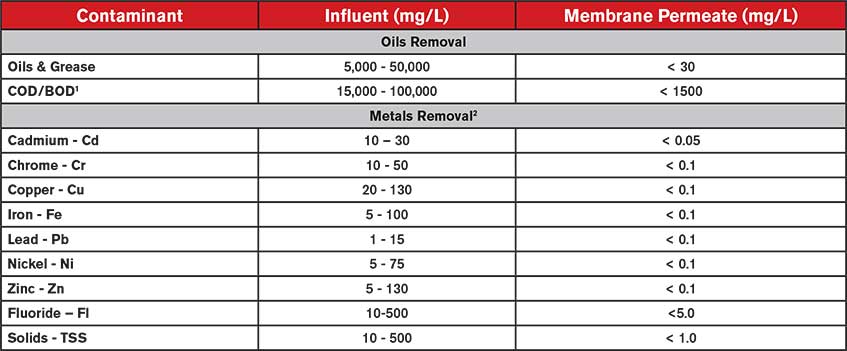

Wastewater produced by industrial processes contaminated with solids, heavy metals, or oil and greases often require treatment prior to discharge or reuse. A treatment system using tubular membrane modules can significantly reduce solids and emulsified oil and greases, and in combination with chemical precipitation, provides excellent reduction of heavy metals (nickel, zinc, copper, lead, chromium, and more). Treated water (permeate or filtrate) is then ready for either disposal into existing municipal waste systems or further treatment for plant reuse/recycle. Tubular ultrafiltration is the best available technology for pretreatment before reverse osmosis systems, increasing recoveries for either process/wastewater recycling or pure water applications.

1 Dependent on influent water quality and source of COD/BOD

2 Pretreatment required

Inside a TMF Module

TMF modules utilize cross-flow filtration. They are composed of 1- or 1/2-inch polyethylene (PE) or polyvinyldene difluoride (PVDF) support tubes that have been coated on the inside with a PVDF material to form a filtration membrane. Next, several of the membrane-coated tubes are bundled into a larger housing to form a single TMF module.

About the TMF System

The TMF system is an excellent treatment system for many uses involving both waste and process water. Combined with proper chemical pretreatment, TMF systems will provide many years of efficient, trouble-free operation. High solids loading allowed by the rugged TMF modules results in a treatment system that surpasses many other types of membrane filtration systems.

TMF System Operation

A typical TMF system operates as follows:

TMF Process Concentration Tank

The purpose of the TMF concentration tank is to ensure that a consistent concentration of solids (between 2-5% slurry) is being pumped to and from the microfiltration or ultrafiltration membranes. The concentration tank is equipped with a level sensor that allows the ultrafilter feed pump to cycle on and off as the tank level varies.

TMF Solids Management

The solids are removed from the concentration tank by a pump. An air-operated positive displacement pump is used. Material is pumped from the concentration tank to a sludge settling tank. The sludge can then be removed from the solids settling tank to a filter press or other solids-handling method. The liquid from the sludge settling tank can be returned to the concentration tank. Occasionally, the operator will need to draw a sample from the concentration tank and do a simple settling test to determine if the sludge pump controls require field adjustment. Online TSS monitoring of the concentration tank is also available.

TMF Permeate Flow

TMF permeate is the water that has passed through the pores of the TMF membrane. It is continually monitored during system operation. If permeate flow drops below a predetermined rate, the TMF system will alert the operator that all or a portion of the modules (depending on module configuration) require chemical cleaning. Permeate from the modules flow under small pressure to the next stage in the treatment system, or to reuse or discharge.

TMF Modules and Chemical Cleaning

The TMF clean-in-place system contains a recirculation pump along with both a chemical cleaning tank and a fresh water tank. The chemical cleaning cycle may take several hours to complete. Cleaning chemicals are mixed in the chemical cleaning tank and are pumped into the membrane modules. The chemicals can be circulated in the modules or allowed to sit in the modules without circulation. Acid solutions are used to remove inorganic scale, while bleach or caustic solutions are used to remove organic materials. Once chemical cleaning has been completed, the TMF modules are flushed with fresh water prior to being placed back in service.

In the past 2 years PRAB has provided equipment saving customers nearly $2.6 million annually by re-purposing their wastewater for reuse or sending to sewer.

Available Options:

Construction Materials:

Piping ……………………………PVC Sch 80

Frame ………….Epoxy coated carbon steel

Enclosure……………………………..Nema 4

Clamps/Fittings……………………Zinc-plated

Lifecycle Services with Lifetime Support: