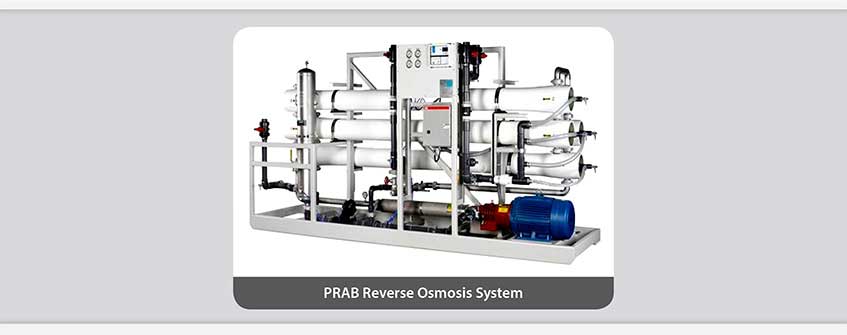

PRAB Reverse Osmosis (RO) Systems effectively remove dissolved salts, colloidal, and suspended matter from the most challenging waste and feed water applications. It is typically used as a final process after ultrafiltration or chemical treatment of incoming water, process water, or industrial wastewater for reuse and/or discharging to your local POTW. PRAB Reverse Osmosis Systems arrive at your site fully tested and ready to clean contaminates from water.

Features and Benefits:

Applications:

All PRAB industrial filtration systems are built using components only with proven membrane technology that will provide reliable, long-term operation. In addition, each system is backed by a 100% Performance Guarantee.

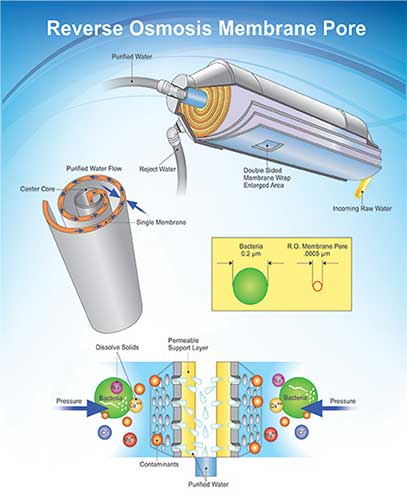

Reverse Osmosis (RO) is a filtration technology used to remove dissolved solids and impurities from water using a semi-permeable RO membrane which allows the passage of water but leaves the majority of dissolved solids and other contaminants behind.

RO membranes require high water pressure (greater than osmotic pressure) to work effectively. Water that passes through the membrane is called permeate and the dissolved salts rejected by the membrane are called concentrate. An RO system that is properly designed and operated can remove up to 99.5% of incoming dissolved salts and impurities.

In the past 2 years PRAB has provided equipment saving customers nearly $2.6 million annually by re-purposing their wastewater for reuse or sending to sewer.

PRAB offers a complete line of pilot equipment that can be used to validate system operation and performance prior to purchase. Pilot units are meant to act as a sample test to provide confidence that the recommended equipment will meet the output requirements of your application.

PRAB Reverse Osmosis systems arrive at your site fully tested and ready to clean contaminates from water. Pretreatment equipment and chemistry are also provided to ensure the optimal performance and lifespan of the system’s membranes.