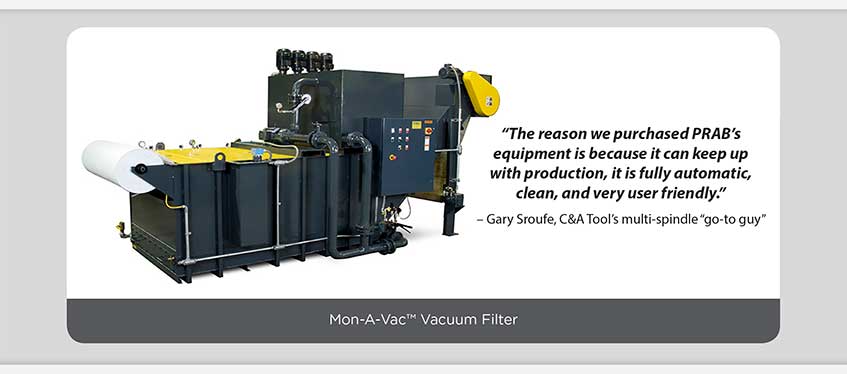

PRAB Mon-A-Vac

Proven to Improve Surface Finish By an Average of 27%

Disposable Media Vacuum Filters to Maximize Contaminant Removal

PRAB’s Mon-A-Vac™ Vacuum Filters utilize a vacuum chamber to draw dirty coolant through the disposable filter media. They apply the proven principle of optimal filtration through contaminate or sludge build-up, forming a cake on the filter media. Filtration is maximized as caking builds up on the media. Standard vacuum filter units are available with flow rates up to 3,000 GPM. Custom-designed vacuum filters are our specialty.

Top Features & Benefits:

- Automatic indexing of media

- Self-monitoring

- Different grades of media available for choice of fluid clarity

- Standard units available with flows from 25 to 3,000 GPM

- Removes high levels of contamination

- Extends tool life

- Improves surface finish of the component part

- Continuous operation

- Simple maintenance and operation

Continuous Operation Eliminates Downtime

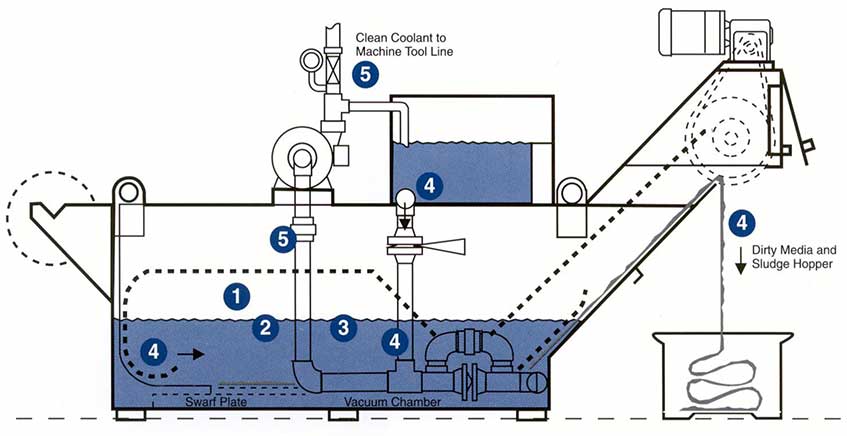

Mon-A-Vac™ System Operation:

- Dirty coolant enters the Mon-A-Vac at the tank inlet directly from the machine tool line.

- A vacuum system draws the dirty coolant through the filter media, causing solids and sludge to build up and cake on the media.

- Cake buildup on the media causes the vacuum in the vacuum chamber to increase. As this occurs, the filter density and filtration efficiency increase.

- When the predetermined vacuum is attained, the vacuum break valve opens, bringing coolant from the clean tank into the suction pump. This equalizes pressure across the media, and the flight conveyor automatically indexes, presenting new media and discharging solids and sludge with the dirty media into a hopper.

- When the vacuum break valve opens, clean coolant from the clean coolant tank is used to feed the machine tool. Upon completion of the indexing cycle, the filter returns to the normal operating mode. The clean tank is continuously and automatically refilled for the next index cycle.

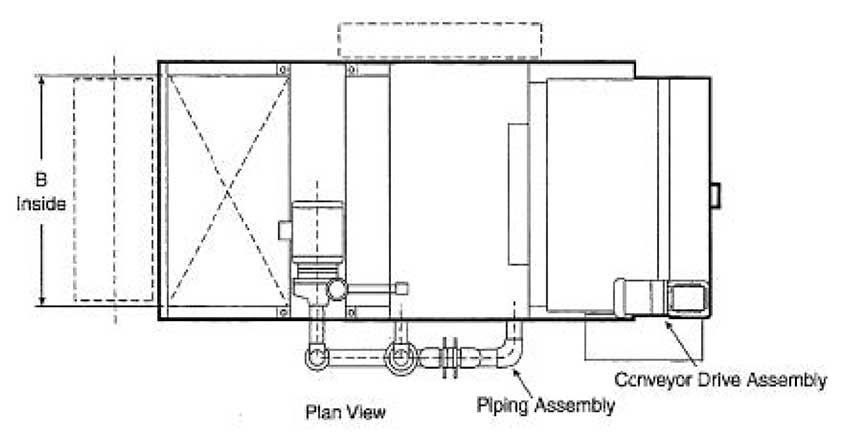

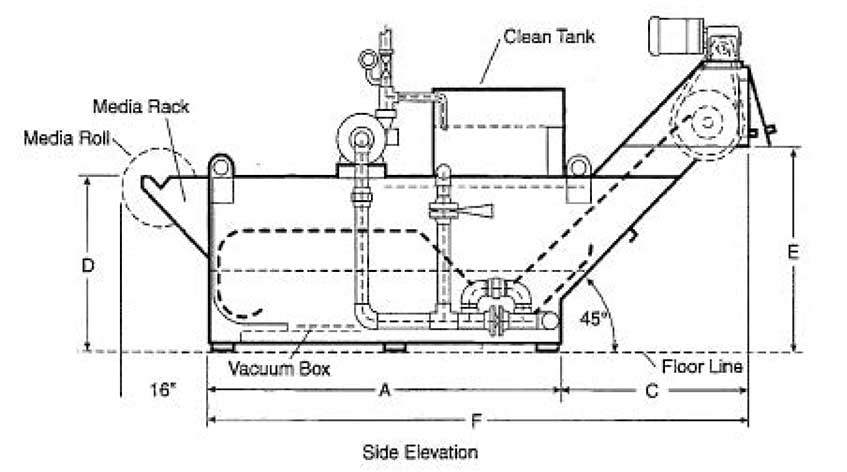

Models and Specifications:

Media Width

Model

A

B

C

D

E

F

38”

VM-9

5’4”

3’8”

2’8”

2’6”

3’0”

8’0”

38”

VM-12

6’4”

3’8”

2’8”

2’6”

3’0”

9’0”

38”

VM-15

7’4”

3’8”

2’9”

2’6”

3’0”

10’0”

51”

VM-20

8’4”

4’8”

3’8”

3’0”

4’0”

12’0”

51”

VM-30

11’2”

4’8”

3’8”

3’0”

4’0”

15’10”

51”

VM-40

14’0”

4’8”

3’8”

3’0”

4’0”

17’8”

51”

VM-50

16’11”

4’8”

3’8”

3’0”

4’0”

20’7”

51”

VM-60

19’9”

4’8”

3’8”

3’0”

4’0”

23’7”

51”

VM-70

22’8”

4’8”

3’8”

3’0”

4’0”

26’4”

72”

VM-40

10’10”

6’5”

4’8”

4’0”

5’0”

15’6”

72”

VM-60

14’10”

6’5”

4’8”

4’0”

5’0”

19’6”

72”

VM-80

18’10”

6’5”

4’8”

4’0”

5’0”

23’6”

72”

VM-100

22’10”

6’5”

4’8”

4’0”

5’0”

27’6”

72”

VM-120

26’10”

6’5”

4’8”

4’0”

5’0”

31’6”

All dimensions are approximate and for reference only.

All models are available with an extended discharge ramp for pit installation or adaptation to any size waste hopper.

Options include a two-pump arrangement with piping and valve that allows one pump to operate while the other is on standby.

To receive a free fluid test contact us today.

Applications:

- All grinding applications

- General machining

- Diecast rinse water

- Stamping operations

- Parts washers

- Plastic recycling

- Tube and rolling mills

- Wire drawing