PRAB Industrial Oil Water Separators

Download PDF

Proven to Reduce Haul-Away Costs Up to 90%

Proven Method for Fluid Reclamation

The PRAB Oil/Water Separator uses a proven coalescing method for gravity separation of oil from water to less than 15 ppm. This system is designed to meet and exceed all performance requirements of U.S. Coast Guard 46CFR162.050 and IMO Resolution A393 (X) of effluent discharge of 15 ppm free and mechanically dispersed oil in water.

Features and Benefits:

- Down-flow gravity coalescing separator

- Reduced haul-away costs up to 90%

- Decreased water consumption

- Increased life of soluble oils, coolants, washwater, rinse water, and pressure wash-down water (or process water)

- Separates oil from water to less than 15 ppm

- Double packed, fixed, porous media bed

- Compact and lightweight

- High quality carbon steel (304 stainless steel units available)

- PVC oil weirs (stainless steel available)

- Self-contained for simple operation

- System includes separator, separator supply pump (electric or air), and floating oil skimmer

Customer Documented Results

Results achieved by Texas fastener manufacturer included:

- Reduced fresh water consumption by a projected 130,000 gallons annually.

- Saved $95,827 in haul-away costs the first year.

Significantly Reduce Water Consumption

Operation:

The oil/water mixture is pumped via a floating skimmer or is gravity fed into the separator. The separator which uses PRAB’s unique gravity/coalescence principle, removes free and mechanically dispersed oil from the influent. Separated oil is then automatically gravity discharged to a waste container. Clean water is discharged by gravity or through an optional discharge pump to the sewer, or back into the process.

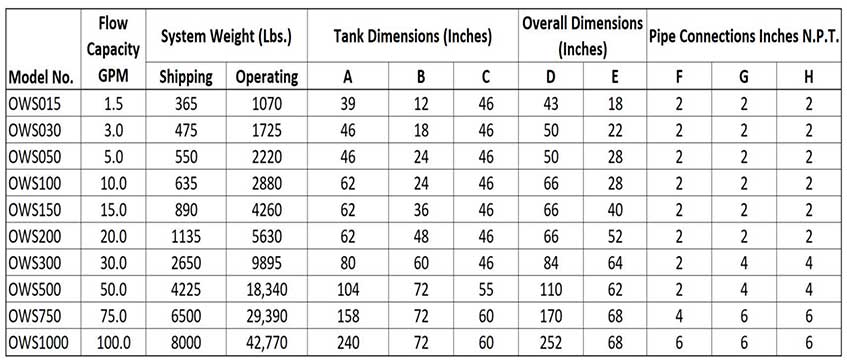

Specifications:

This standard oil/water separator system is made of high quality carbon steel with epoxy coating (304 stainless steel units are also available). Oil weirs, as well as all piping, are PVC, galvanized steel, or stainless steel separator. Supply pump is offered in a variety of materials and is driven by an electric motor. An air operated double diaphragm (AOD) pump is also available.

Options:

- Electrical controls

- Level switches

- Lid with vent

- Clean water discharge pump

- Oil holding tank

- Oil discharge pump

- Other customer specified controls and alarms

Applications:

- Rinse Water

- Wash Water

- Wastewater

- Steam cleaning operations

- Compressor blowdown

- Machinery pits

- Gas stations

- Non-contract process water

- Refueling areas