Evaled® Evaporation Technology

Download PDF

Proven to Reduce Water Costs of Up to 99%

Evaporation Solutions for Industrial Water & Wastewater Treatment

Backed by the PRAB Difference

Evaled Evaporation TechnologyReduce Washwater & Detergent Cost Up to 75%Evaporation is not only a natural phenomenon, but also a

clean separation technology that has been recognized as a Best Available Technique in several

wastewater treatment processes.

EVALED® Evaporators are Industrial Systems that Accelerate the Natural Evaporation ProcessEvaled evaporators are fully automatized, standardized, modular units that are low in energy consumption and have a low CO2 footprint. Capacities range from 1 to 200 tons per day (43-53,000 gpd) of distillate from wastewater treatment.

These highly reliable evaporators are effective in reducing wastewater volume and producing a high quality, reusable distillate (ZLD). They are an effective solution for concentrating and removing salts, heavy metals and a variety of hazardous components. All evaporators undergo a Factory Acceptance Test (FAT) with water before shipment.

In the past 2 years PRAB has provided equipment that saved customers nearly $2.6 million annually by repurposing their wastewater for reuse or sending to sewer.

Benefits of EVALED®

- Disposal cost reduction

- Wastewater volume reduction

- Water recycling and reuse

- Valuable components recovery

- High outlet quality

- ZLD (Zero Liquid Discharge)

- High level of automation

- Option for remote control

- Quality certification (ISO 9001/2008)

Contact us to request a quote today

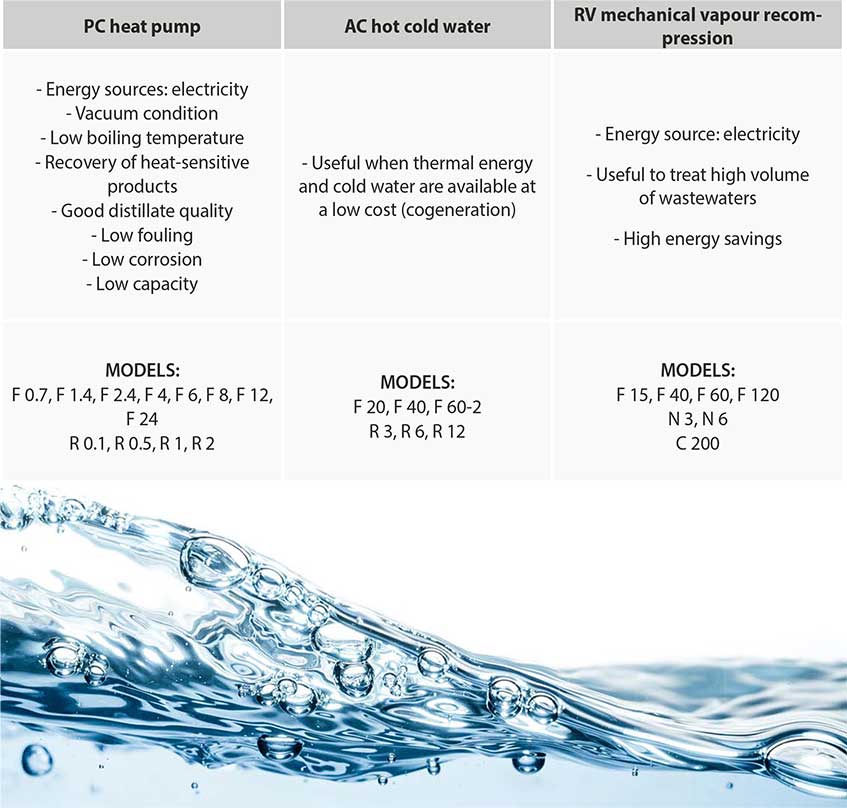

No Air Emissions – EverEvaled Range & ModelsThree different evaporation technologies can be adapted to suit our clients’ water treatment needs.

See Proven Results at prab.com today

Full Spectrum IndustrialWater & Wastewater Treatment SystemsMore Than 3,000 Units Installed Worldwide

Markets & Applications:

- Mechanical & surface treatments (automotive, aviation, appliances, parts for furniture)

- Healthcare (pharma, cosmetics)

- Chemical

- Waste, biogas, biofuels

- Photovoltaic & microelectronics

- Food & beverage

- Graphic arts

- Power

- Oil & gas

- Mining & primary metals

- Other industrial processes

Materials

Evaled is designed with the most suitable materials in order to safely treat aggressive liquids. Resistance to corrosion is a primary feature of every Evaled evaporator, essential when dealing with extremely concentrated liquids.

Austenic Stainless Steel

Uses: alkaline liquids, acidic liquids (pH>4) with a low percentage of chlorides, oil emulsions, liquids from flexographic printing.

Nickel Alloy

Uses: very acidic liquids (pH>2) with high content of chlorides, fluorides and metal, anodizing wastewater, special applications.

Superduplex Stainless Steel

Uses: acidic liquids (pH>3) with high chlorides and metals content, galvanic wastewater, landfill leachate.

Silicon Carbide (SiC) – PC Type Only (KT-Series)

Uses: pickling wastewater, chromic acid recovery, aggressive liquids.

Contact us to request a quote today