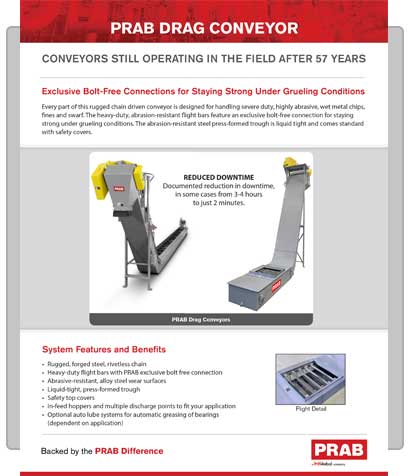

PRAB Drag Conveyor

Conveyors Still Operating in the Field After 57 YearsExclusive Bolt-Free Connections for Staying Strong Under Grueling ConditionsEvery part of this rugged chain driven conveyor is designed for handling severe duty, highly abrasive, wet metal chips, fines and swarf. The heavy-duty, abrasion-resistant flight bars feature an exclusive bolt-free connection for staying strong under grueling conditions. The abrasion-resistant steel press-formed trough is liquid tight and comes standard with safety covers.

System Features and Benefits

- Rugged, forged steel, rivetless chain

- Heavy-duty flight bars with PRAB exclusive bolt free connection

- Abrasive-resistant, alloy steel wear surfaces

- Liquid-tight, press-formed trough

- Safety top covers

- In-feed hoppers and multiple discharge points to fit your application

- Optional auto lube systems for automatic greasing of bearings (dependent on application)

Flight Detail

Flight Detail

Backed by the PRAB Difference

Proven to Raise Productivity Up to 60%

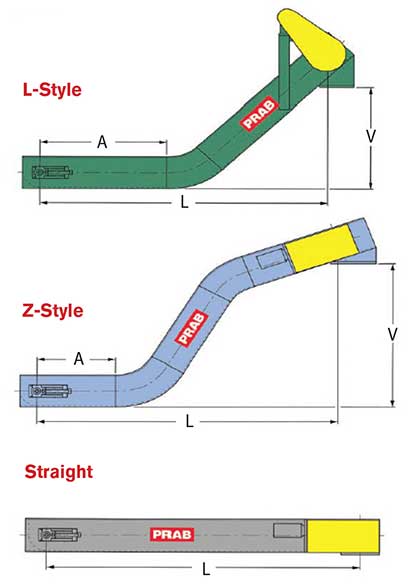

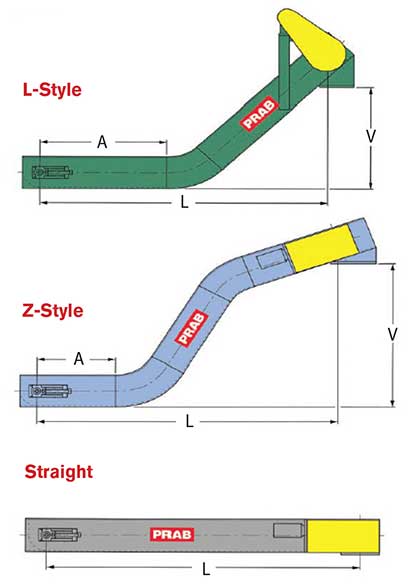

Models and Configurations

PRAB offers two models of drag conveyors– Series #348 and Series #458 available in three configuration styles designed to convey materials ranging in weight and bulk density. This scrap material conveyor is also available with in-feed hoppers and metering plates, and can be customized with coolant pumps for integration with a PRAB chip processing and fluid filtration system.

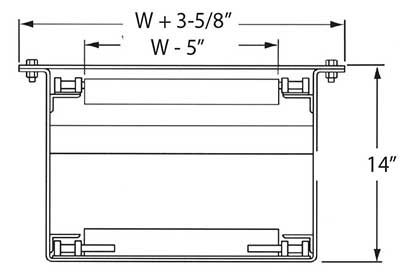

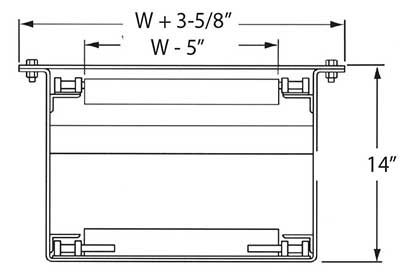

Series #348

- 3” pitch- 348 chain

- 3/16” side section

- 1/2” x 2” flight

- 24” radius bend

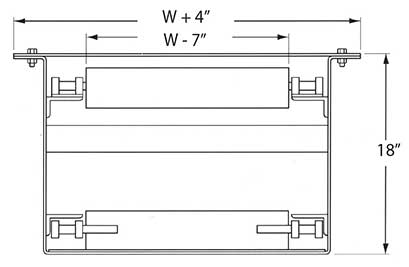

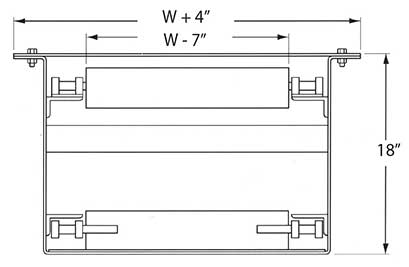

Series #458

- 4” pitch- 458 chain

- 1/4” side section

- 5/8” x 3-1/2” flight

- 36” radius bend

Dimensions

Dimensions

A = Lower Horizontal

B = Length

V = Discharge Height

Lighter-Duty Drag Conveyor for Chip Removal at CNC Machines

PRAB also designs a lighter-duty, low profile version of its drag-conveyor that easily integrates under certain types of CNC machines- for removal of chips at the source.

The light-duty drag conveyor offers zero carryover and features a grated end plate to allow fluid from chips to exit and collect in a liquid-tight trough.

Contact us to request a quote today