A research laboratory center for a multinational company in the pharmaceutical industry develops a variety of innovative therapeutic products to help with respiratory diseases, rare diseases, musculoskeletal and cardiovascular diseases. High quantities of water are used in their process and it was resulting in a high volume of wastewater and disposal costs.

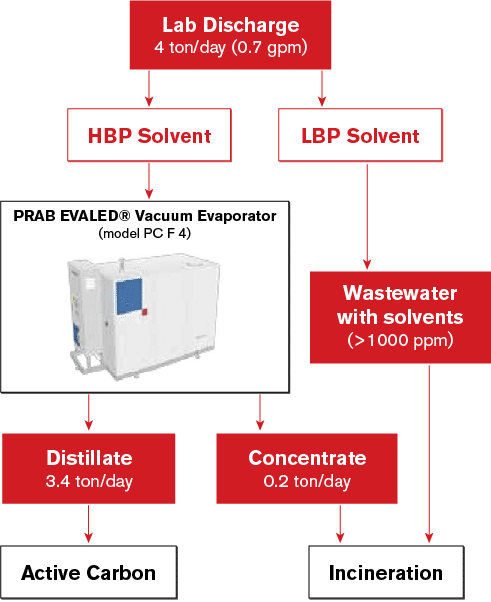

During the typical day, the lab was discharging approximately 4 tons of effluent a day. It needed to treat this water for reuse back into the process and to separate this water from the concentrate. The concentrate could then be incinerated.

Because no two wastewater streams are exactly alike, in order to find the best solution to meet the company’s goals, a careful review of their process was completed, along with a thorough testing and analysis of the wastewater. It was then determined that an EVALED® Vacuum Evaporator (Model PC F4 FF) would be the best solution.

| Parameters | u.m. | Waste In | Distilled Out | Concentrate Out |

|---|---|---|---|---|

| COD | ppm | 100 – 3,000 | <160 | <50,000 |

| TS at 105˚C | % | 0.01 – 1 | – | <20 |

| Conductivity | µS/cm | 200 – 8,000 | <20 | – |

| TSS | ppm | 50 – 200 | 0 | – |

| HBP Solvents | ppm | 1-1,000 | <5* | – |

*active carbon