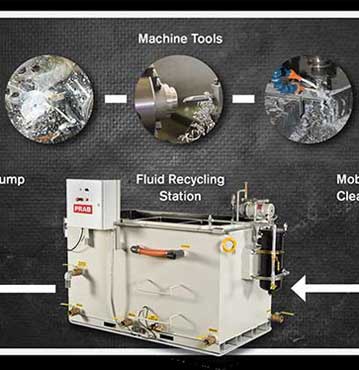

The Benefits of Coolant Recycling

Outweigh the Up-Front Costs

If you need a more effective and profitable way to reclaim your metalworking fluid, a modern coolant recycling equipment is the proven answer. Implementing the right fluid reclamation system provides fast ROI and enhances profits, equipment lifespan and employee safety. Costs of Not Filtering Machine Tool Coolant While water comprises most of the coolant, it’s the concentrate in it that […]