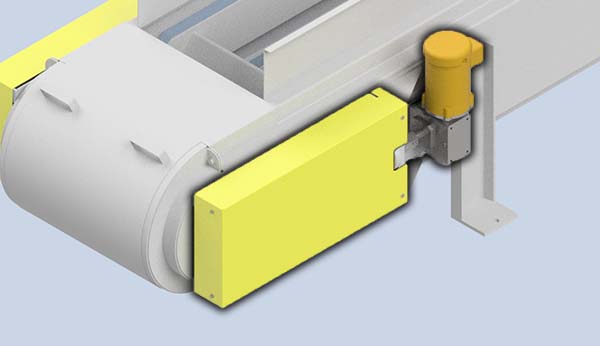

Introducing the Auto-take Up – Eliminate Downtime Associated With Conveyor Belt Adjustment

We’re pleased to introduce the Auto-Take Up System, a conveyor enhancement that automatically tightens belts and eliminates the need for manual adjustments. As the chains on conveyance systems get older, they stretch. This is one of the most common causes of premature belt wear and unplanned conveyor maintenance. A stretched chain can cause the belt to slip off of the […]