A top manufacturer of TFT-LCD panels needed to reduce its sludge production and wastewater disposal costs at two of its plants—complying with local environmental legislation. This sludge and water waste was produced in both of the plants’ rinse lines, as part of their copper(Cu) etching production process.

Because no two wastewater streams are exactly alike, in order to find the best solution to meet the plant’s goals for each specific plant application, a careful review of their processes were completed, along with a thorough testing and analysis of the wastewater of each plant’s rinsing line. It was then determined that a PRAB EVALED® Vacuum Evaporator would be the best solution for each rinse line process.

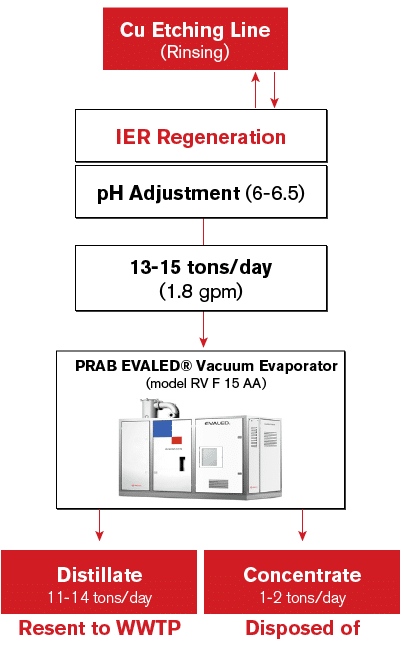

At plant-1 a model RV F 15 AA vacuum evaporator was the solution for effectively cleaning the wastewater coming from their Cu-etching rinsing process and the new process was implemented.

| Parameters | u.m. | Waste In | Distilled Out | Concentrate Out |

|---|---|---|---|---|

| pH | 6-6.5 | 9 | – | |

| TDS | ppm | 4,000-50,000 | <10 | – |

| Conductivity | µS/cm | <8,000 | <30 | |

| TS at 105˚C | % | 0.6-5 | 30 | |

| Chloride | ppm | <500 | <300 | – |

| Ammonium | ppm | 500-5,000 | <500 |

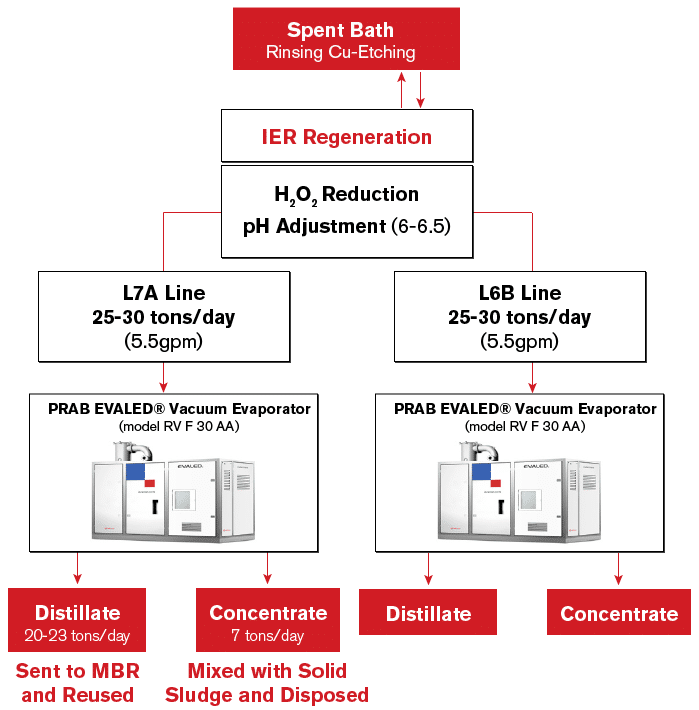

Two model RV F 30 AA vacuum evaporators were determined to be the solution for effectively cleaning the wastewater coming from the rinsing lines at plant 2. One evaporator was implemented into the L7A Rinsing Line, and the other was installed as part of the L6B Rinsing Line.

| Parameters | u.m. | Waste In | Distilled Out | Concentrate Out |

|---|---|---|---|---|

| pH | 6-6.5 | 9 | – | |

| COD | ppm | 80,000 | <4,000 | – |

| Conductivity | µS/cm | <50,000 | <20 | |

| TS at 105˚C | % | 5-9 | 30 | |

| Chloride | ppm | <500 | <300 | – |

| Ammonium | ppm | 5,000-15,000 | <500 |

After adding PRAB EVALED® Vacuum Evaporator’s to the manufacturer’s rinsing line processes, each plant saw a significant reduction in sludge and disposal costs. Now, 70-90% of distillate is recovered and reused in the production processes—which has resulted in system paybacks within 8-months of installation.