A specialty chemicals company that produces systems and products for the construction and motor vehicle industry was looking to improve both energy and material efficiency as part of their sustainability efforts, which is a key component of the company’s innovation drive.

As part of its sustainability goals, the company was making every effort to reduce its resource consumption. For that reason, it needed to reduce wastewater disposal volumes with a low energy consumption solution.

Because no two wastewater streams are exactly alike, in order to find the best solution to meet the company’s goals, a careful review of their process was completed, along with a thorough testing and analysis of the wastewater. It was then determined that PRAB’s EVALED® Vacuum Evaporators would be the best solution.

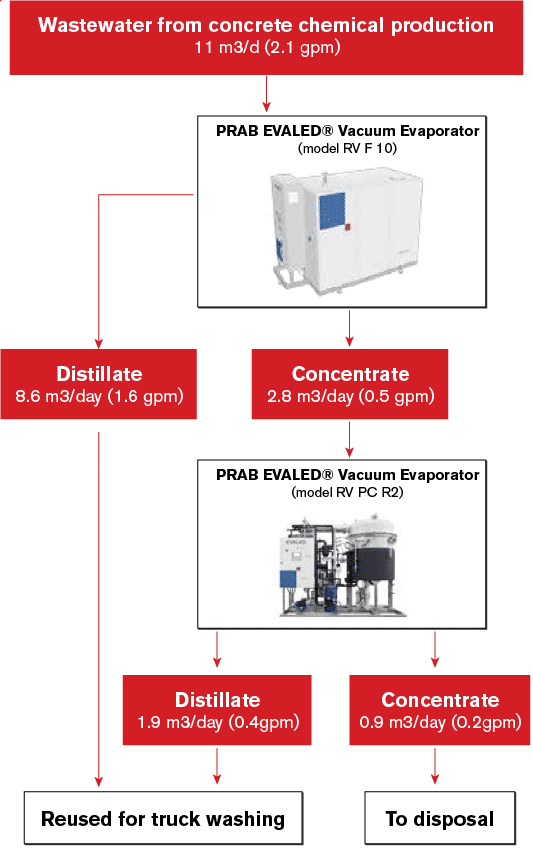

Two EVALED® evaporators: Model RV F 10 and Model PC R 2 were installed as part of their process solution:

The model RV F system is a mechanical vapor recompression evaporator designed to achieve the most reliable heat exchange with minimum fouling and scaling— requiring very low energy consumption.

The model PC R system is a heat pump vacuum evaporator system designed to treat liquids at a low temperature that have a high content of dissolved solids. This system is able to manage a high level of fouling and scaling phenomena (viscous liquids and sediment presence).

After adding the PRAB EVALED® Vacuum Evaporators to the process, the company has seen significant cost reductions.

The results achieved include: