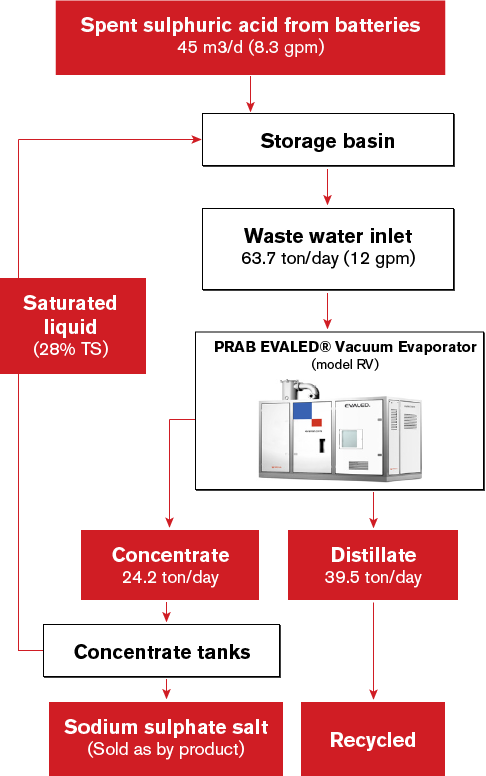

Recover water and Sodium Sulfate from spent sulphuric acid from recycled batteries

PRAB EVALED® Vacuum Evaporator (RV F 60 FF)

Zero Liquid Discharge and recovery of 80% sodium suplhate for resale

A company who recycles over 3,000,000 automotive battery units a year, and produced over 40,000 tons of lead every year needed to recover the water and Sodium Sulfate (Na2SO4) coming from the spent sulphuric acid in the batteries, in order to cut costs.

This would cut costs by allowing the company to reuse the wastewater back into the process and it would generate revenue by converting the sodium sulphate into a useful material that could be sold as part of a product for society.

Sodium sulfate is used in many products including home laundry detergents, carpet fresheners, cement, starch, cattle feed additives, and more. About half of the world’s sodium sulfate comes from natural sources, while the other half is a byproduct of other processes, such as battery recycling.

Because no two wastewater streams are exactly alike, in order to find the best solution to meet the recycler’s goals, a careful review of their process was completed, along with a thorough testing and analysis of the wastewater. It was then determined that the PRAB EVALED® Vacuum Evaporator would be the best solution.

New Treatment Process Results:

| Parameters | u.m. | Waste In | Distilled Out | Concentrate Out |

|---|---|---|---|---|

| pH | – | 6.5 | 6 | – |

| TS at 105˚C | % | 12 | <.01 | >80 |

| Conductivity | µS/cm | >100,00 | <80 | – |

| Sulphates | ppm | >70,000 | <50 | – |

| COD | ppm | 95 | <60 | – |

| Chlorides | ppm | 48 | 13 | – |

| Lead | ppm | 1.3 | <1.0 | – |