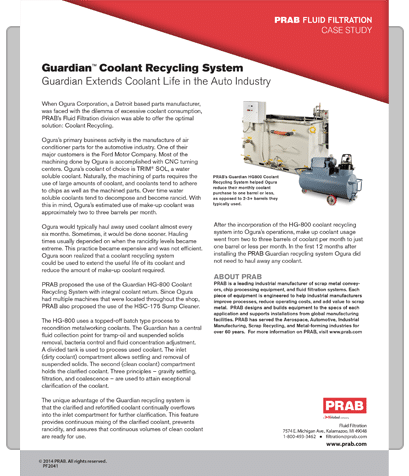

Auto Parts Manufacturer Reduces Coolant Purchase Costs and Eliminates Used Coolant Disposal in First 12 Months

Challenge When Ogura Corporation, a Detroit based parts manufacturer, was faced with the dilemma of excessive coolant consumption, PRAB’s Fluid Filtration division was able to offer the optimal solution: Coolant Recycling. Ogura’s primary business activity is the manufacture of air conditioner parts for the automotive industry. One of their major customers is the […]