Reduce volumes of large bundles and stringy turnings. This scrap metal equipment delivers dry, shovel-grade chips and reclaims up to 99% of valuable coolants and cutting oils.

PRAB High Volume Aluminum Systems

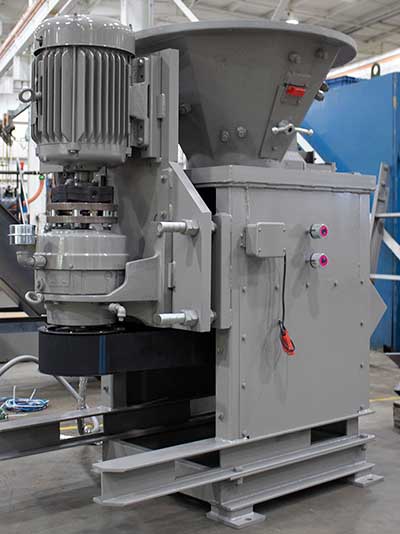

Aluminum turnings are one of the most difficult types of material to process, especially in large volumes. PRAB delivers the reliable, durable, and dependable aluminum processing system your operations demand. The skid steer loader feeds wet, stringy material into the hopper of the 6” pitch steel belt conveyor. The PRAB Steel Belt Conveyor carries the material up and meters it into the crusher. The crusher reduces the stringy chips into smaller, flowable chips and discharges them onto the PRAB Drag Conveyor. The PRAB Drag Conveyor transports the material up and into two diagonal shaft chip wringers. The PRAB Chip Wringers separate the coolant from the chips using nearly 700 Gs of centrifugal force. The settling tank captures the coolant for recycling. An integral PRAB Drag Conveyor discharges the settled fines back into the material flow. The PRAB Chip Wringers internally generate air pressure to pneumatically discharge dry chips. The dry chips travel through the pneumatic piping and cyclones to the PRAB Magnetic Separator. The PRAB Magnetic Separator removes ferrous particles from the stream of material and discharges them into a container, while dry aluminum chips continue onto the weight belt. The weigh belt measures throughput of dry material in process and deposits it into a blower. The blower pneumatically transports the chips across the plant to one or more cyclones, which dissipate the air and deposit the chips into storage bunkers.

Product Brochures

PRAB Chip Processing Systems All Product Brochure

White Paper

White Paper: Green Engineering

Other Downloadable Content

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Product Brochure: PRAB Diagonal-Shaft Wringer

Download Proven to Increase Scrap Value Up to 25% Produce 98% Dry Chips and Reclaim Cutting Fluid for Increased Waste Value The PRAB E-Series Chip System is a dependable, fully automated system for reclaiming valuable cutting fluid from wet metal chips and turnings. This compact unit was designed for small to medium material volumes and can process Aluminum, […]

Download Up to 4x the Metal Turnings Volume ReductionReduce Metal Turnings to Flowable Chips PRAB Metal Turnings Shredders reduce volumes or metal turnings by shredding them into flowable chips for higher value when sending to the recycler. Units are a safe and cost-effective way to process all types of steel turnings and other metalworking scrap– using less space […]

Download Conveyors Still Operating in the Field After 57 YearsExclusive Bolt-Free Connections for Staying Strong Under Grueling ConditionsEvery part of this rugged chain driven conveyor is designed for handling severe duty, highly abrasive, wet metal chips, fines and swarf. The heavy-duty, abrasion-resistant flight bars feature an exclusive bolt-free connection for staying strong under grueling conditions. The abrasion-resistant […]