A die cast company in the Midwest contracts with automotive and other industrial OEM companies to design and manufacture die cast parts from Aluminum, Zinc, and Plastic. The die caster recognized the need to improve the efficiency of their Aluminum remelt processes.

The Die Cast industry as a whole has seen shrinking profit margins since the 2008 financial crisis according to a State of the Industry study published by the North American Die Casting Association (NADCA). (http://www. diecasting.org/docs/information/stateoftheindustry-march2015.pdf). Recognizing the growth and profit margin increase potential with improved operating processes on scrap management, the die caster analyzed rework, quality of raw material, furnace burn rates and energy consumption to pinpoint the production area with the shortest ROI for capital investment toward process efficiency. The data analysis showed the remelt line for Aluminum trim scrap and off-spec parts had the highest deviations and therefore offered the best internal rate of return.

The challenge in metal scrap handling is deeper than surface-level observation would render. Conveyors and furnace feeders need to be sized and engineered to handle the variances in scrap characteristics. The size, shape, and weight of the wide range of trim and off-spec parts need to be accounted for when designing a scrap management system for die cast applications. PRAB, Inc. was selected as the partner to perform the design and manufacturing of the scrap handling system, due to the company’s 65 years of experience in the design and manufacturer of complete systems for scrap metal. PRAB evaluated the scrap parameters, conducted a site audit, and discussed goals and objectives with the team leaders at the plant. The goal of the project was outlined to design and implement a new automated scrap management system that would improve worker safety, automate the scrap management process, feed the furnaces effectively, decrease temperature fluctuations in the melt bath, and maintain or decrease energy costs associated with the Aluminum remelt process.

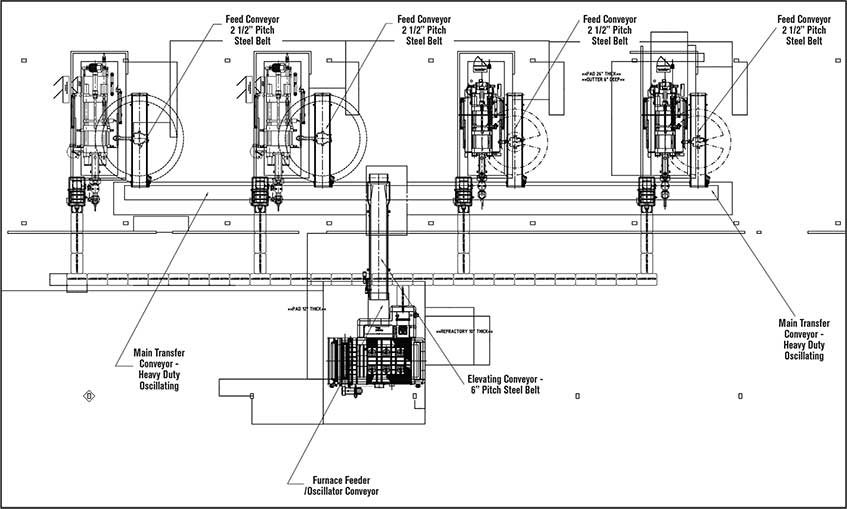

The Aluminum line at the facility had experienced temperature fluctuations in the melt bath and difficulty maintaining consistent uptime due to the fluctuations. When the remelt was delivered to the injection molds if the temperate was below specification the mold did not fill properly, this caused the off-spec rate to increase on finished parts. The challenge in the existing process stemmed from surge loads of material that were dumped into the main furnace. The surge in material created hot and cold spots in the melted Aluminum, causing inconsistent material quality at the molds and the higher off-spec rate. In addition, the temperature fluctuations created a variation in the viscosity of the melted material causing clogging at some mold injection locations and increased maintenance requirements to clean them. PRAB evaluated the entire process and redesigned the system to optimize the furnace feeding process and improve consistency of the remelted material. The new scrap handling system consisted of four 2-1/2” pitch steel belt conveyors at each of the trim press discharge chutes. Two main transfer conveyors are 80’ long x 42” wide Oscillating horizontal motion conveyors which run perpendicular to the steel belt conveyors. Each Oscillator conveyor collects the trim scrap and off-spec parts from two lines. The main transfer conveyors carry material horizontally approximately 80 feet. The scrap is delivered onto a 6” pitch Z-Style steel belt conveyor. A Z-style conveyor means the conveyor path runs horizontally, vertically, then horizontal again. The steel belt Z-style conveyor elevates and carries material to the inlet level of the furnace. The scrap travels from the Z-style steel belt to a furnace feeder. The furnace feeder is a short Oscillating conveyor that pushes material into the furnace. The operation of the Oscillating conveyor is critical to the efficiency of the furnace because of the unique motion of this conveyor. The gentle vibratory motion moves material forward and creates a metered distribution into the furnace. The furnace feeder is equipped with a Stainless Steel heat shield and discharge chute. The entire scrap handling system is fully automated with integral controls, warning alarms, and programmed for DCS integration.

The die cast company wanted to improve their operating efficiency to meet increasing customer demands, improve profitability, and maintain a clean and safe working environment. Through evaluation of the scrap handling process within the plant, the team at the die caster focused on all aspects of their operations and improved the output and quality of the production lines. As the Midwest-based die cast company continues to grow and expand within their core business and through acquisitions, the company will use the streamlined and automated processes at this plant location as the model for operational excellence.