PRAB Tramp Oil Separator

Proven to Cut New Coolant Purchases Up to 75%

Solve Issues Associated with Tramp-Oil

Tramp-oil separators use gravity flow and coalescence to remove free-floating and mechanically dispersed tramp-oils, bacteria, slime, inverted emulsions, and more from individual machine sumps, central systems, and wash tanks. With a PRAB system you can cut new coolant purchases up to 75%, reduce your hazardous waste volumes up to 90%, and get a payback on your system in as little as 6-9 months.

System Features:

- Mobile options

- Compact, efficient, complete system

- Unattended operation

- Minimal plant space required for installation

- Air or electric powered

- Systems available to process 180 to 9,000 gallons per hour and higher

- Manual and automatic air sparging system

- Add magnetic separator, pre-filtration and polishing filter

- Gravity flow and pump

Top Benefits:

- Clean Sumps

- Reduces new fluid purchase costs by up to 75%

- Reduces cost of washwater detergents and disposal

- System payback in 6-9 months

- Reduces hazardous waste volumes by up to 90%

- Reduces tramp oil up to 99% in a single pass

- Separated tramp oils can be sold or recycled

- Minimal maintenance

Reduce Fluid Disposal Costs by Approximately 90%

Eliminate 99% of Tramp-Oils in a Single Pass

Tramp-oils allowed to accumulate in a coolant or washwater system will cause operating problems, such as machine downtime, increased tool wear, cleaning and filtering problems. Preventive maintenance and good housekeeping practices help reduce tramp-oils, but they are never completely eliminated.

The PRAB Tramp-Oil Separator extends the production life of oil-based, semi-synthetic, and synthetic coolants as well as alkaline washwaters by removing free-floating and dispersed tramp-oils from the coolant reservoir or central system.

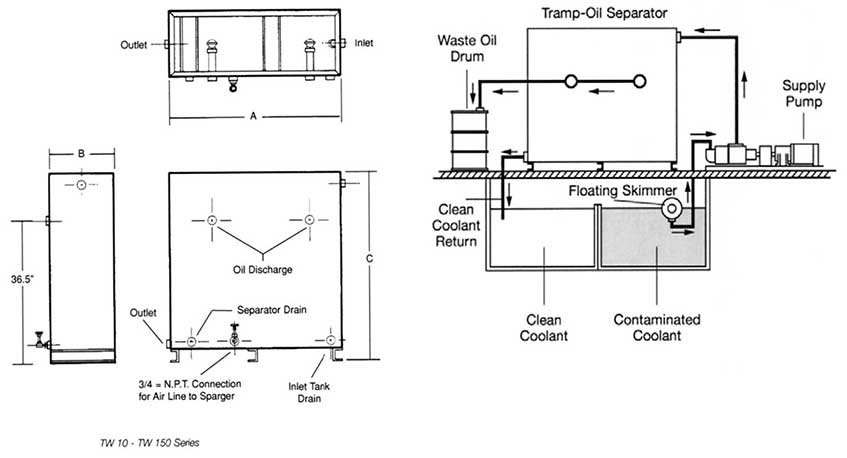

Model

Crossflow

TW3

TW5

TW10

TW15

TW25

TW50

TW75

TW100

TW150

Flow Capacity (USGPM)

2

3

5

10

15

25

50

75

100

150

A

24″

12″

24″

48″

60″

72″

96″

96″

120″

144″

B

12″

8″

16″

18″

24″

30″

36″

48″

60″

72″

C

18″

36″

36″

46″

46″

46″

46″

48″

60″

72″

Standard units operate up to 150°F. Higher temperature units available.